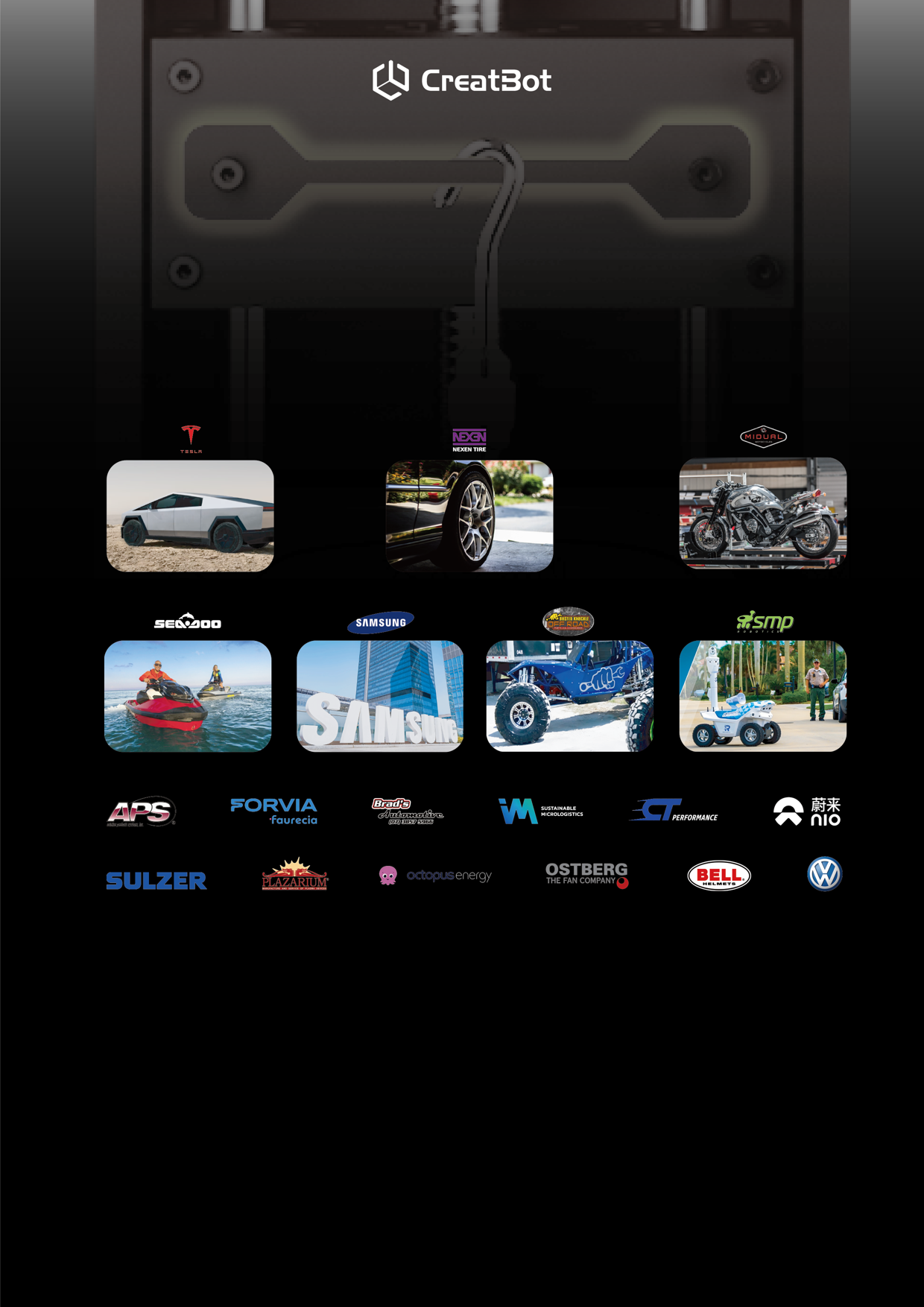

F430NX

VS

X1C

Test Filament

ABS High strength & toughness, ideal for mechanical tests.

ASA ABS-like strength, excellent UV/weather resistance.

D600 Pro2 Hs

VS

H2d

Test Filament

PACF High rigidity, heat resistance, but moisture-absorbent.

PET-CF High rigidity, stability, creep resistance, for precision parts.

Test Content

Each group of printers uses corresponding consumables to print test specimens in the XY direction and Z direction for comparison.

F430NX

VS

X1C

XY direction

Z direction

F430NX

VS

X1C

XY direction

Z direction

XY direction

Z direction

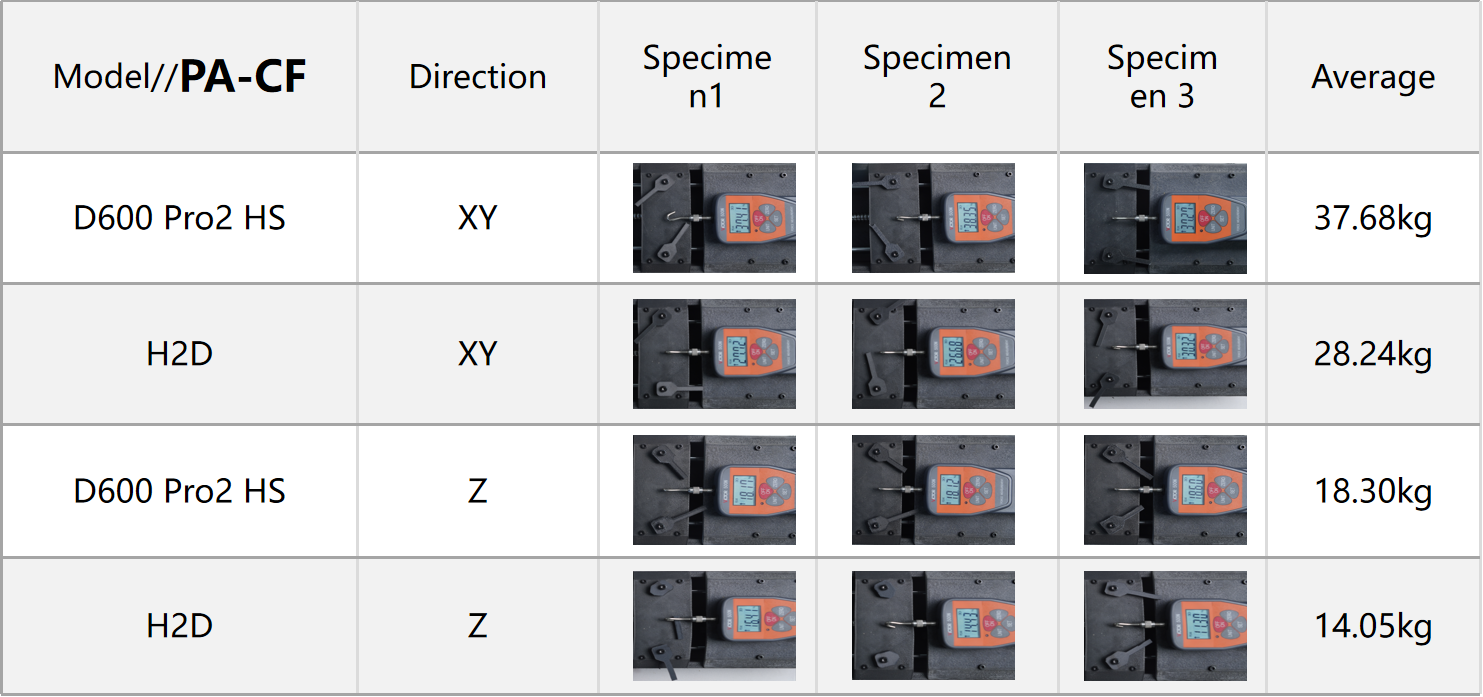

D600 Pro2 HS

VS

H2d

XY direction

Z direction

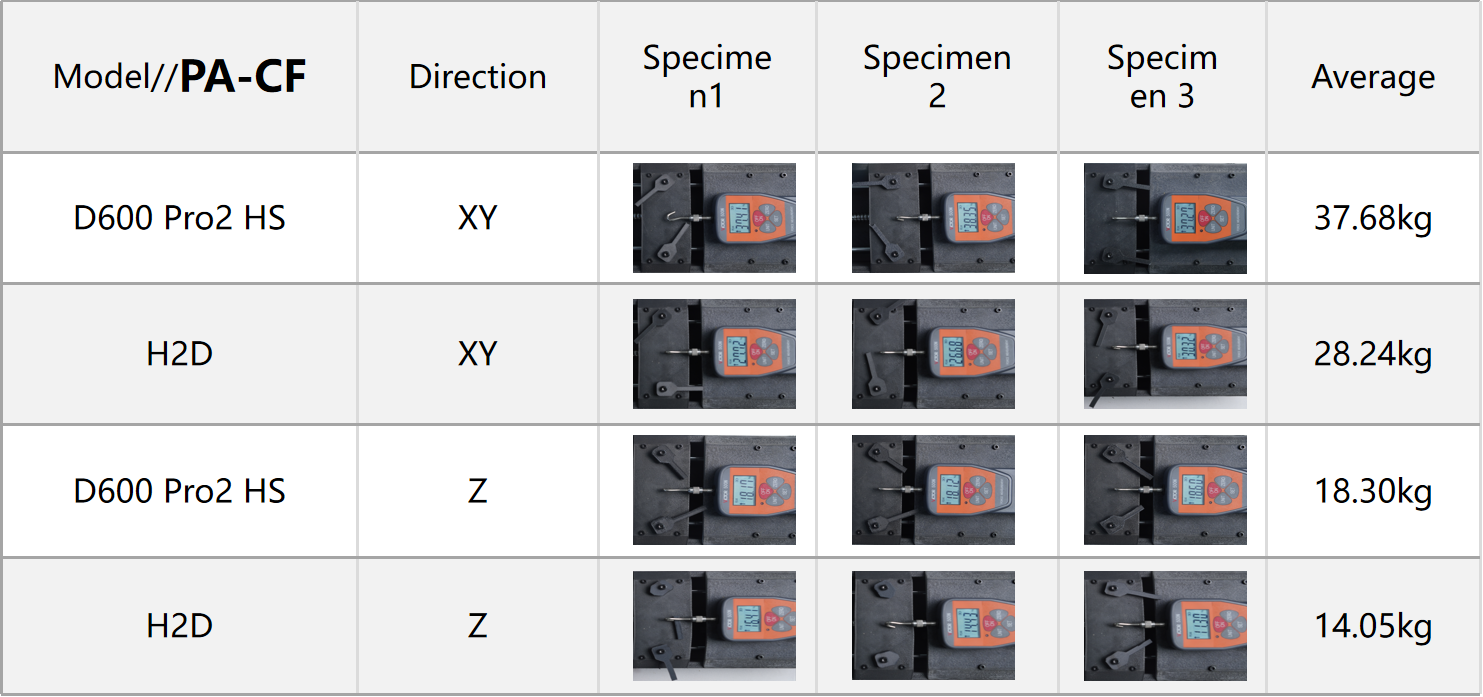

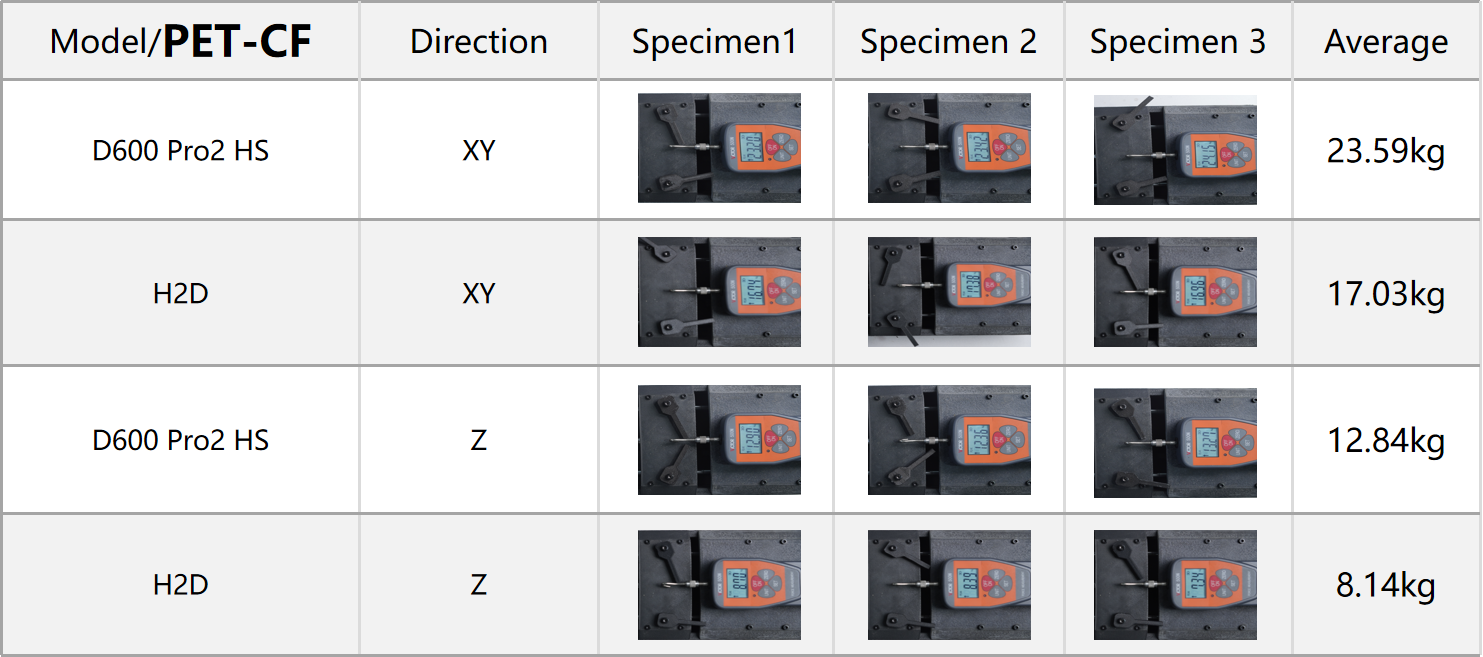

D600 Pro2 HS

VS

H2d

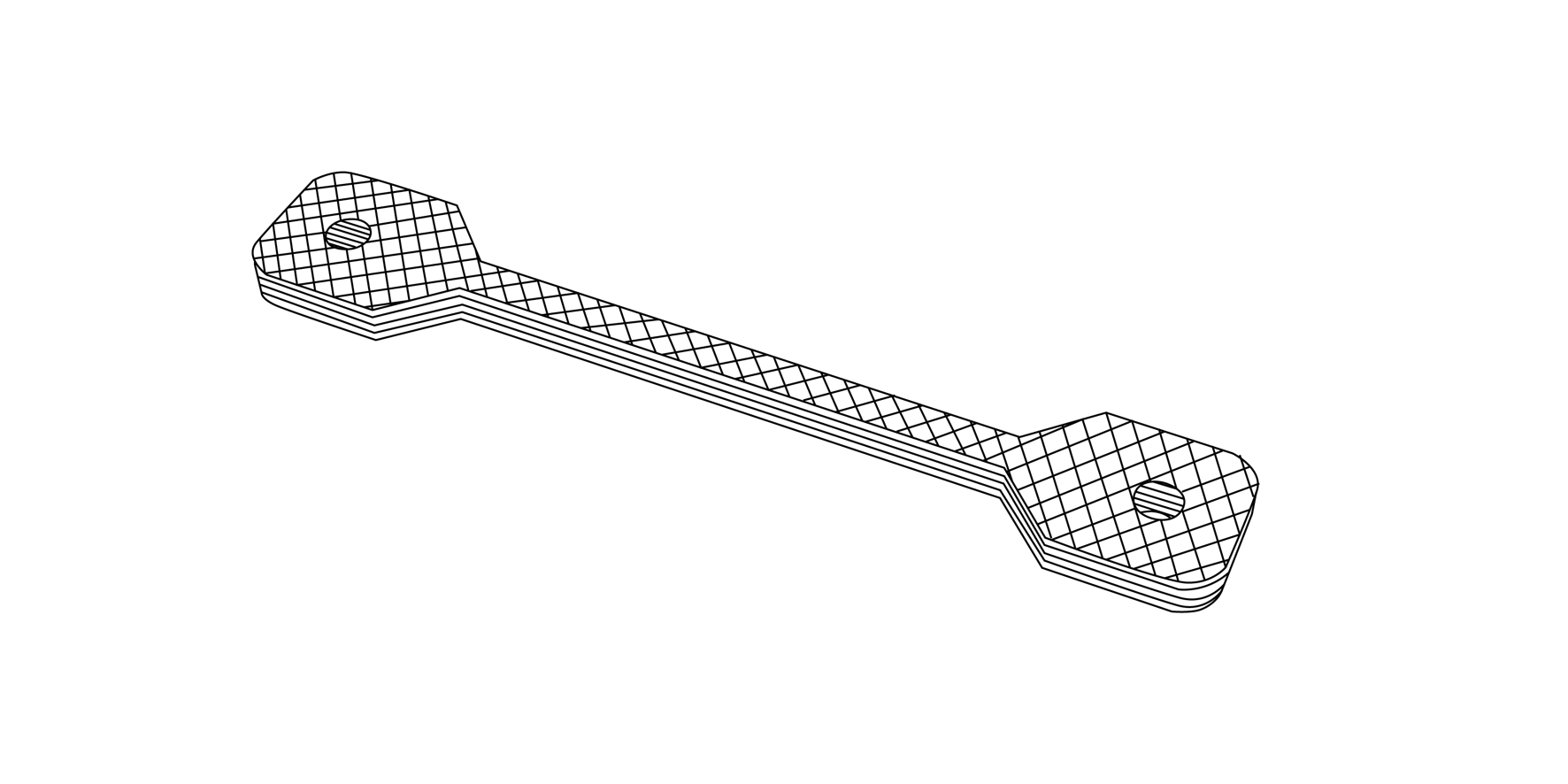

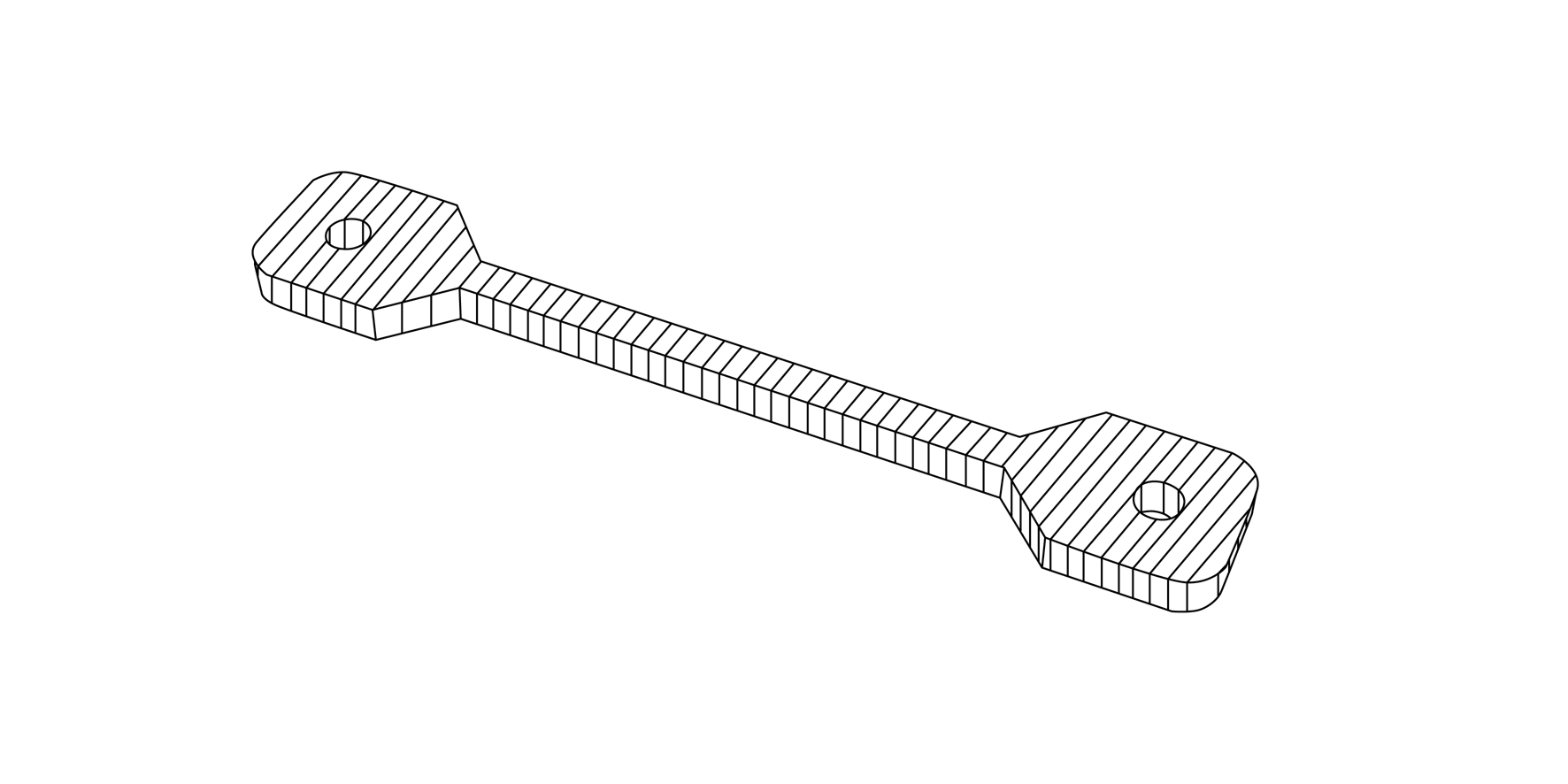

Print specialized test specimen models.

XY direction

Place the specimen's XY direction as the force-bearing direction (printed lying flat) and compare strength and cross-sectional properties.

Z direction

Place the specimen's Z direction as the force-bearing direction (printed standing upright) and compare strength and cross-sectional properties.

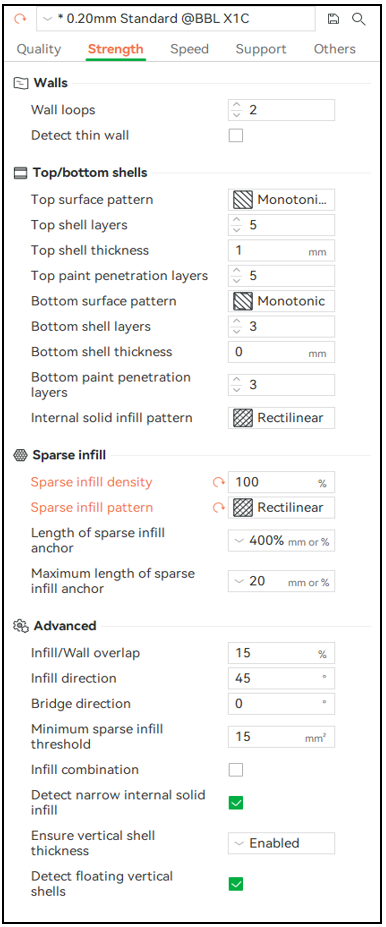

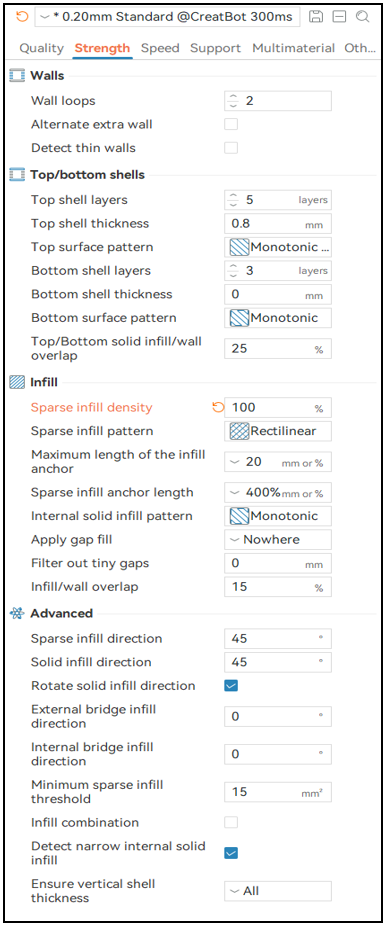

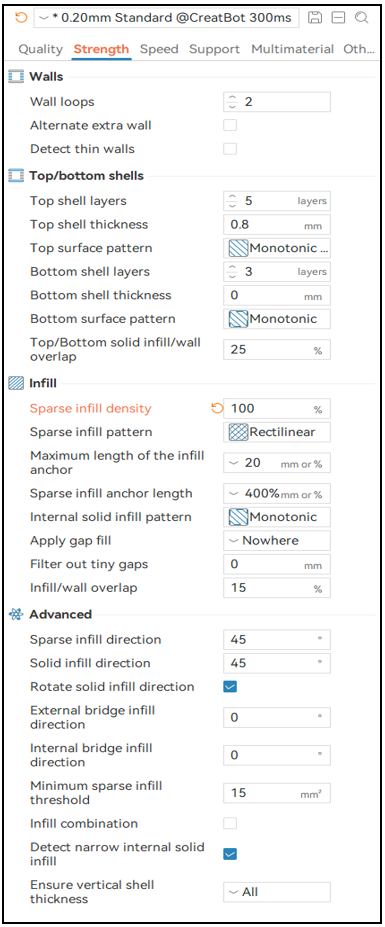

F430NX

VS

X1C

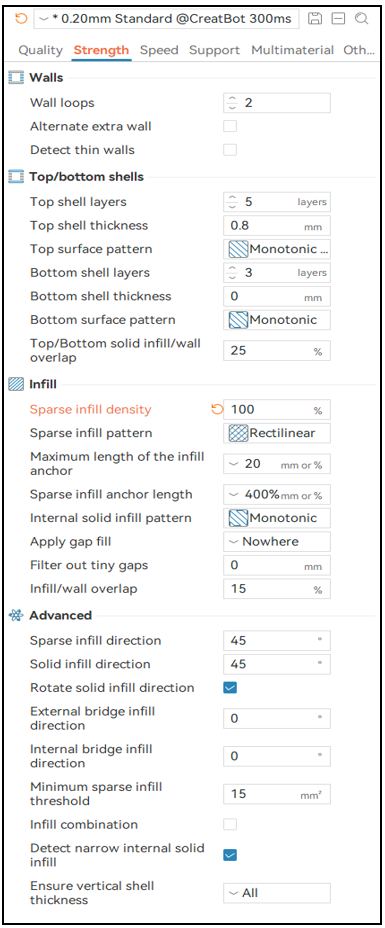

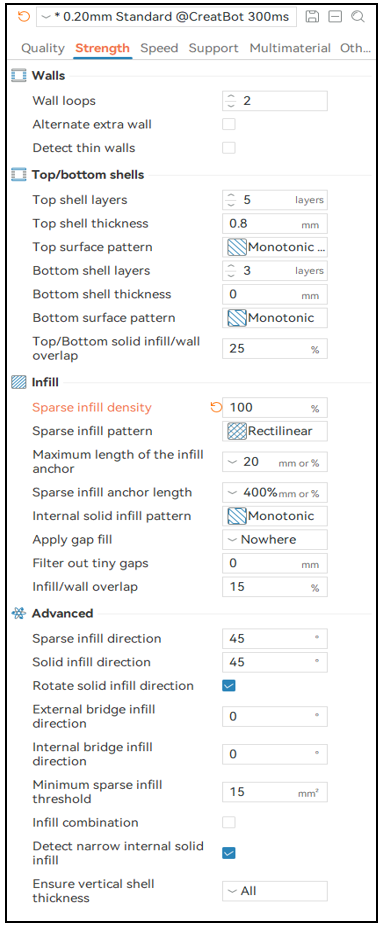

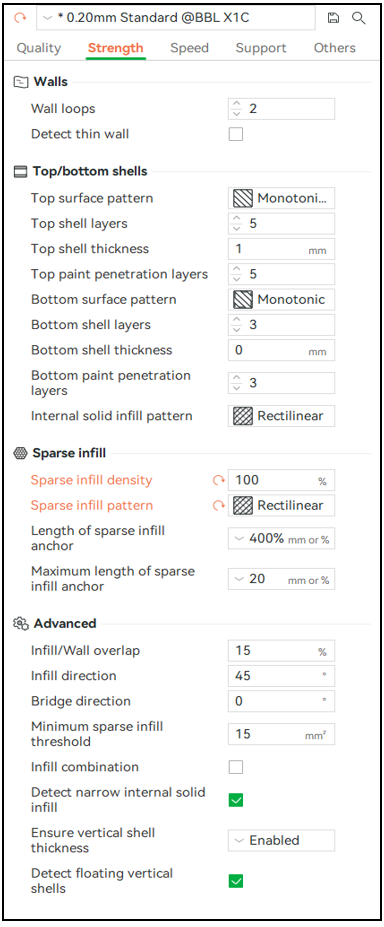

Identical slicing parameters for both printers in each group.

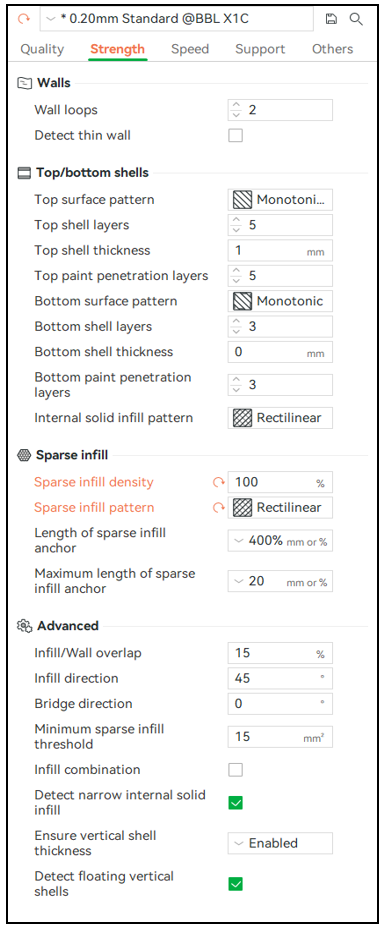

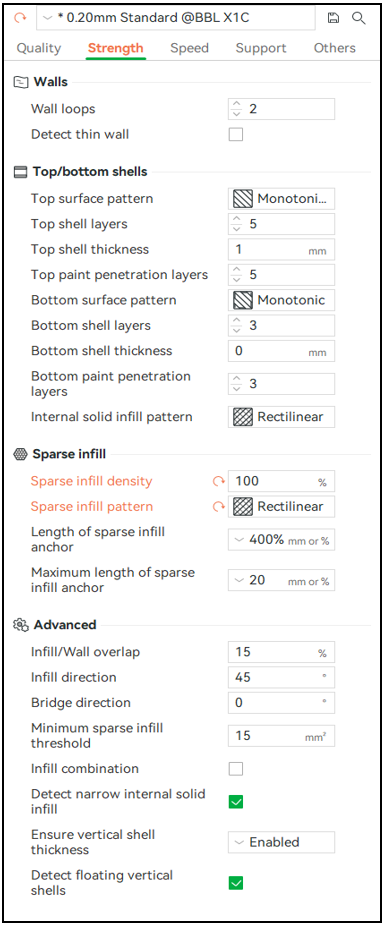

D600 Pro2 HS

VS

H2D

Identical slicing parameters for both printers in each group.

Test Method

Setup Principle

Fix the load gauge to the frame and secure the specimen to the sliding platform. Connect the load gauge hook to the specimen. The motor drives the ball screw to move the platform upward at a constant speed until the specimen fractures. Record the peak load value at fracture.

Print at least 3+ samples each for XY and Z directions per material to minimize errors.

Load gauge unit: kg.

Calculate the average tensile strength and compare strength percentages.

F430NX

VS

X1C

D600Pro hs

VS

H2D

Test Data Summary

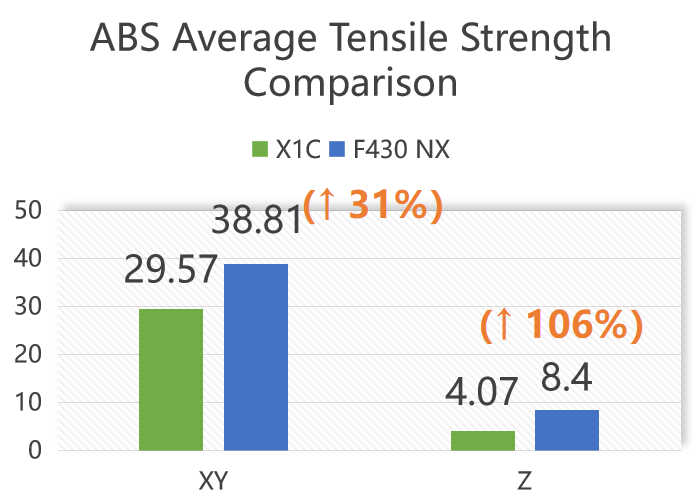

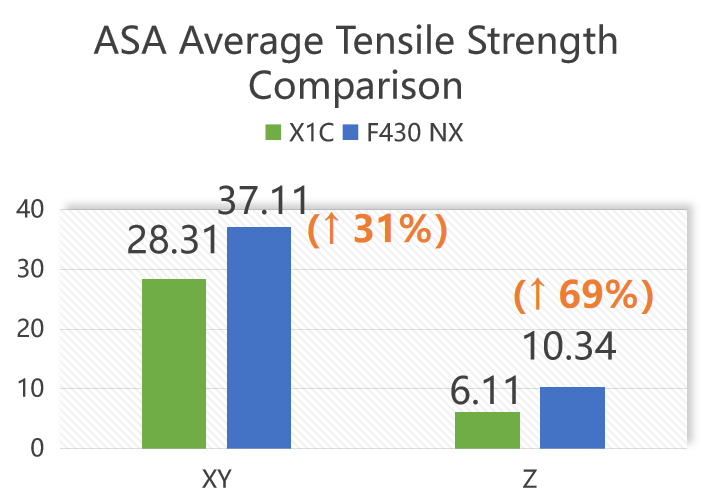

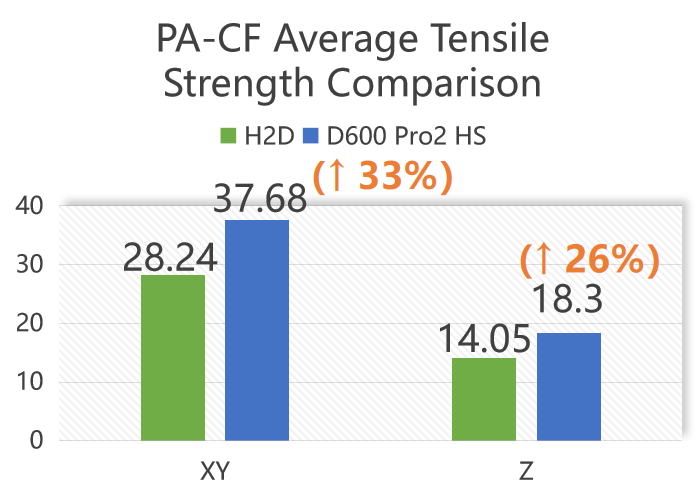

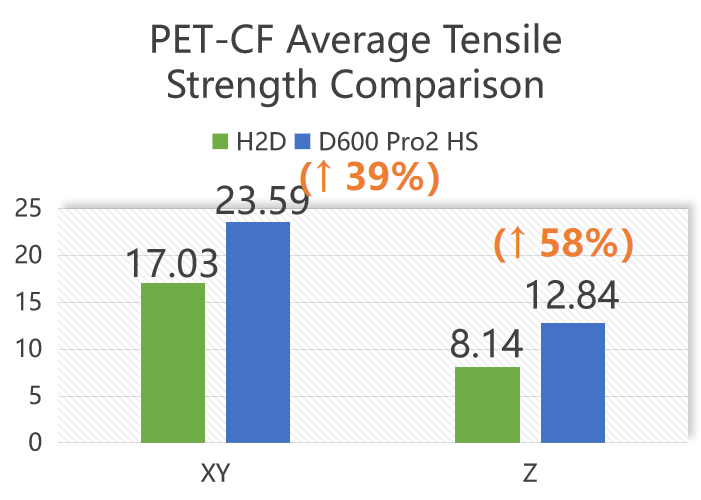

| Test materials | Test direction | CreatBot VS bambu Lab | Strength increase |

|---|---|---|---|

| ABS | XY direction | F430 NX VS X1C- | +31% |

| Z direction | F430 NX VS X1C- | +106% | |

| ASA | XY direction | F430 NX VS X1C- | +31% |

| Z direction | F430 NX VS X1C- | +69% | |

| PA-CF | XY direction | D600 Pro2 HS vs H2D- | +33% |

| Z direction | D600 Pro2 HS vs H2D- | +26% | |

| PET-CF | XY direction | D600 Pro2 HS vs H2D- | +39% |

| Z direction | D600 Pro2 HS vs H2D- | +58% |

What This Data Means for You

Z-Axis Strength is the Benchmark of Industrial Grade

A up to 106% improvement means parts from consumer-grade 3D printers are like a fragile stack of cards with weak interlayer adhesion. CreatBot's fully enclosed, high-temperature chamber ensures powerful layer bonding, manufacturing reliable parts that are robust in all directions.

Achieving Nearly "Isotropic" Reliability

We significantly minimize the inherent "anisotropy" weakness of 3D printing. This allows the components you design to deliver stable, predictable performance regardless of load direction, meeting the demands of rigorous industrial applications.

Unlocking the True Potential of Engineering Materials

Only industrial-grade equipment provides the stable, high-temperature environment required by high-performance materials like PA-CF and PET-CF. This ensures your investment in materials translates into their intended performance.

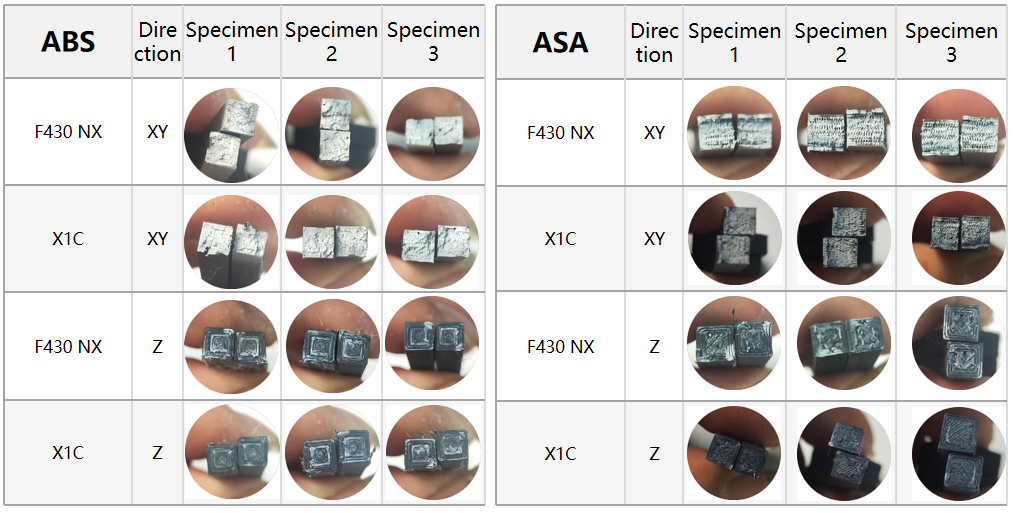

F430Nx VS X1c-Comparison of XY/Z direction cross-sections of test specimens

Stress whitening observed in cross-sections — This phenomenon, known as "stress whitening," is a typical characteristic of engineering plastics.

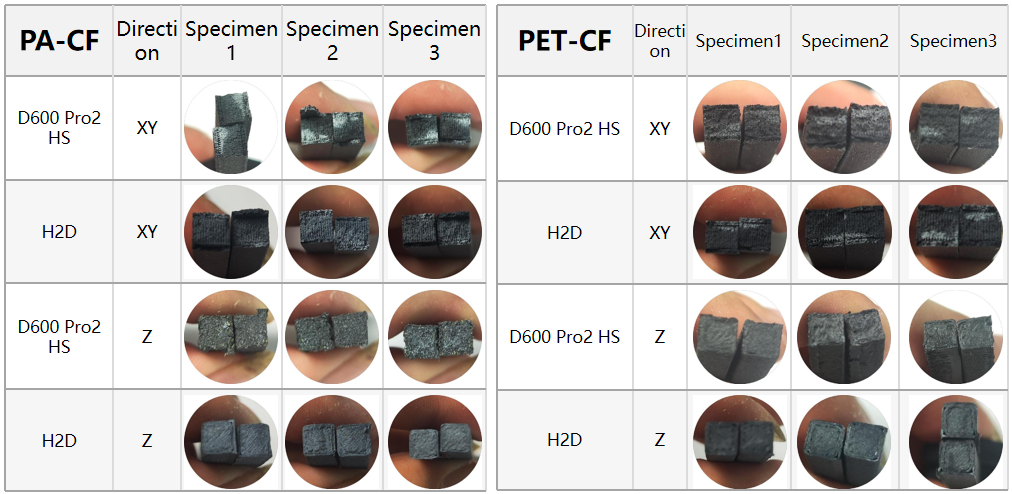

D600Pro2Hs VS H2d-Comparison of XY/Z direction cross-sections of test specimens

Note: Cross-sections of each sample may be enlarged for viewing.

Broken test spline samples