01

3D Printing: An Innovative Tool in the Automotive and Motorcycle Industry

Traditional electric vehicle seat cushion manufacturing: mold opening → injection molding → assembly, with a cycle as long as 30 days, and it's as heavy as if tied with sandbags. The benefits brought by 3D printing technology to manufacturing in this field are remarkable. It has significantly shortened the product development cycle. In the past, it took months to complete the design and sample production of parts, but now, with 3D printing, it can be achieved in just a few days or even hours. This not only enables companies to quickly respond to market demands but also allows them to promptly launch innovative products and seize market opportunities. Meanwhile, 3D printing supports the manufacturing of complex structures. Some irregularly shaped parts that are difficult to process with traditional techniques can be easily realized with 3D printing technology, providing the possibility for lightweight vehicle design, effectively reducing energy consumption, and improving performance.

02

Details Make the Difference

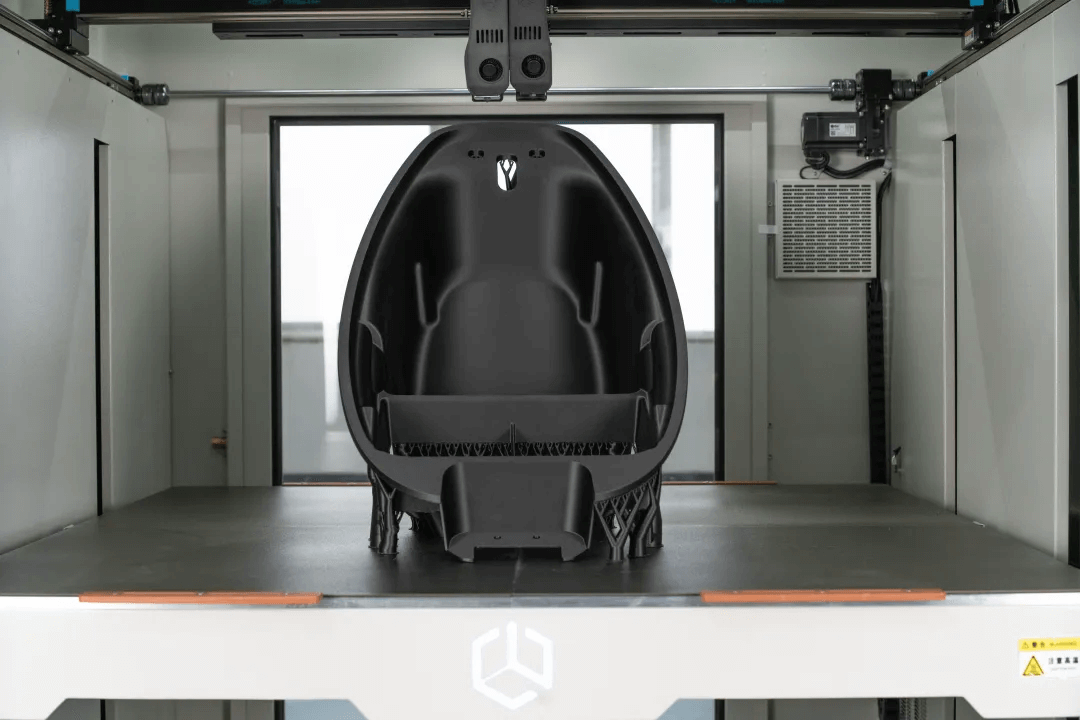

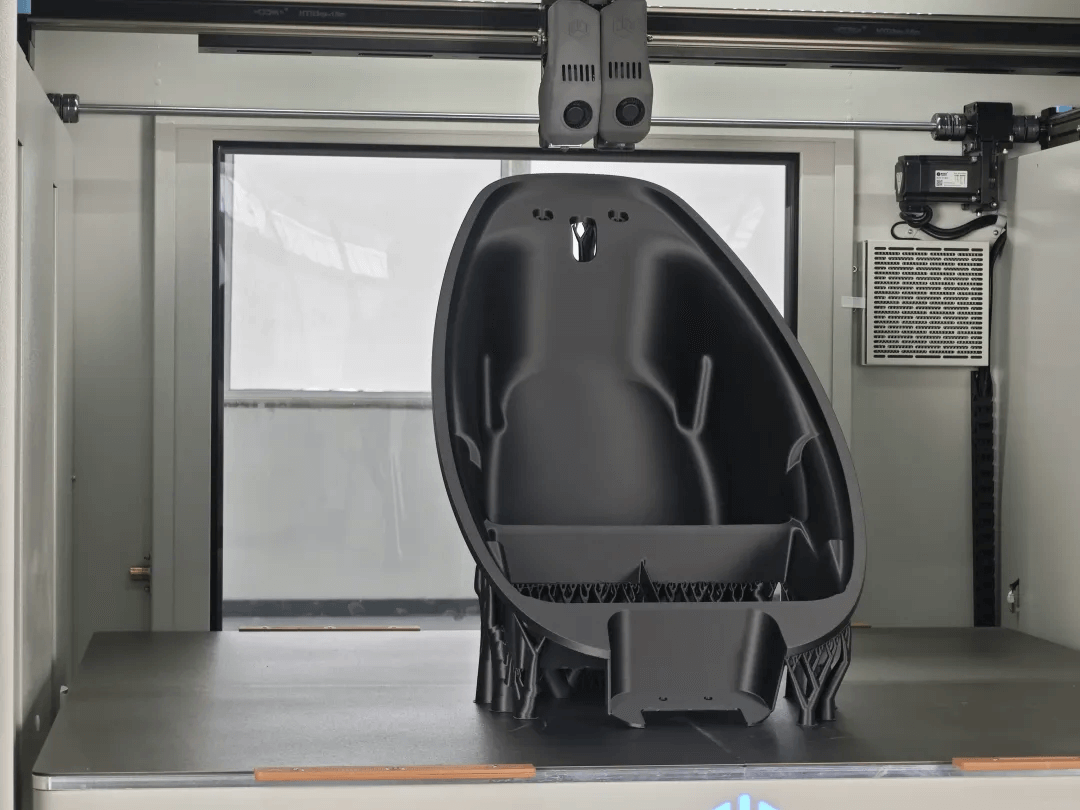

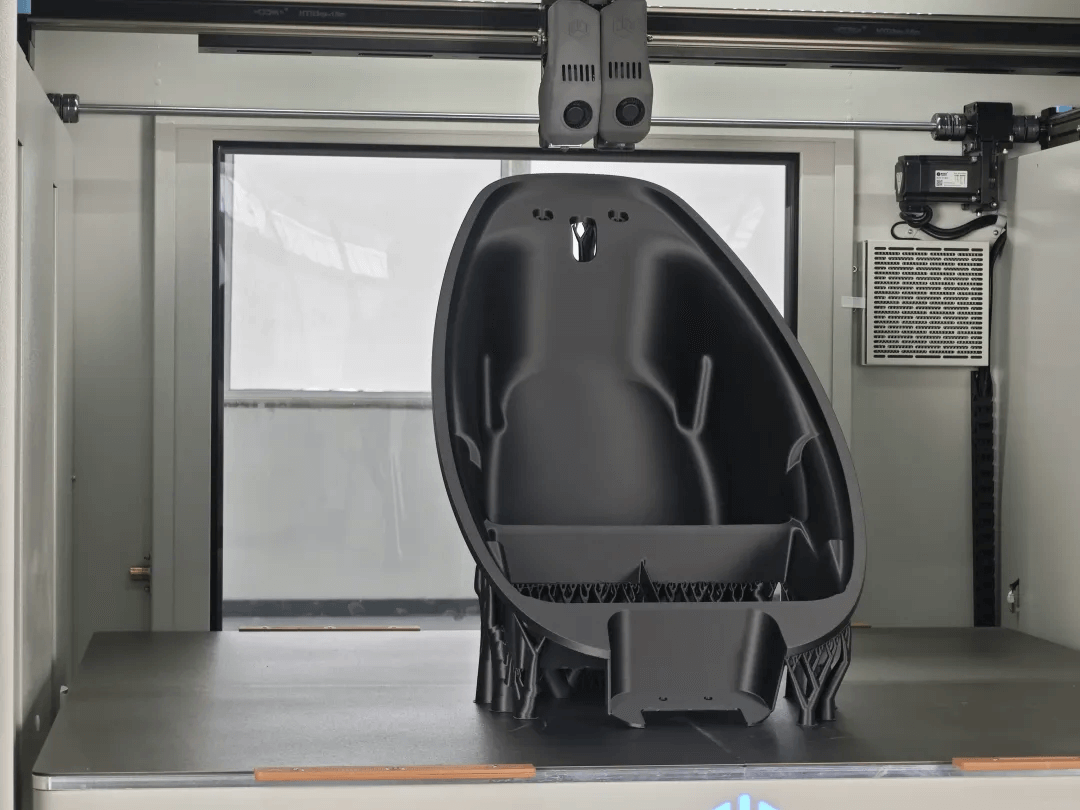

Electric Vehicle Seat —— The high precision of 3D printing ensures a smooth and delicate seat surface. At the same time, it reduces weight while ensuring strength, bringing more ease and convenience to the development process.

▲ Electric Vehicle Seat © Creatbot Technology

• Material: PET-CF

• Weight: 2.4 kg

• Printing Time: 65 h

• Dimensions: 750*390*375 mm

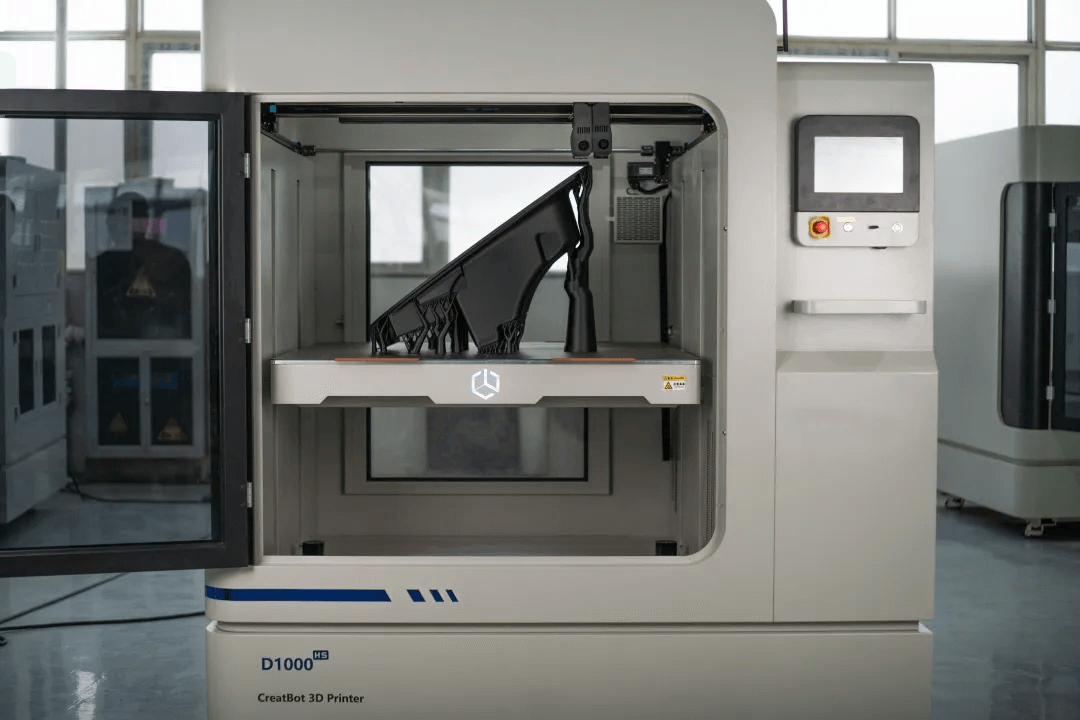

▲ D1000 HS © Creatbot Technology

▲ D1000 HS © Creatbot Technology

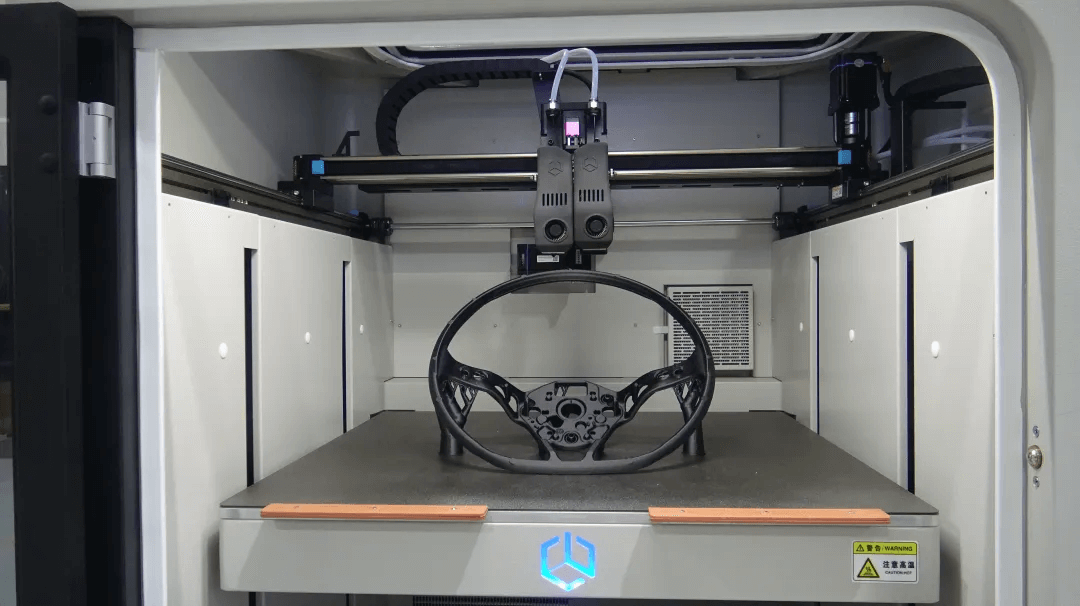

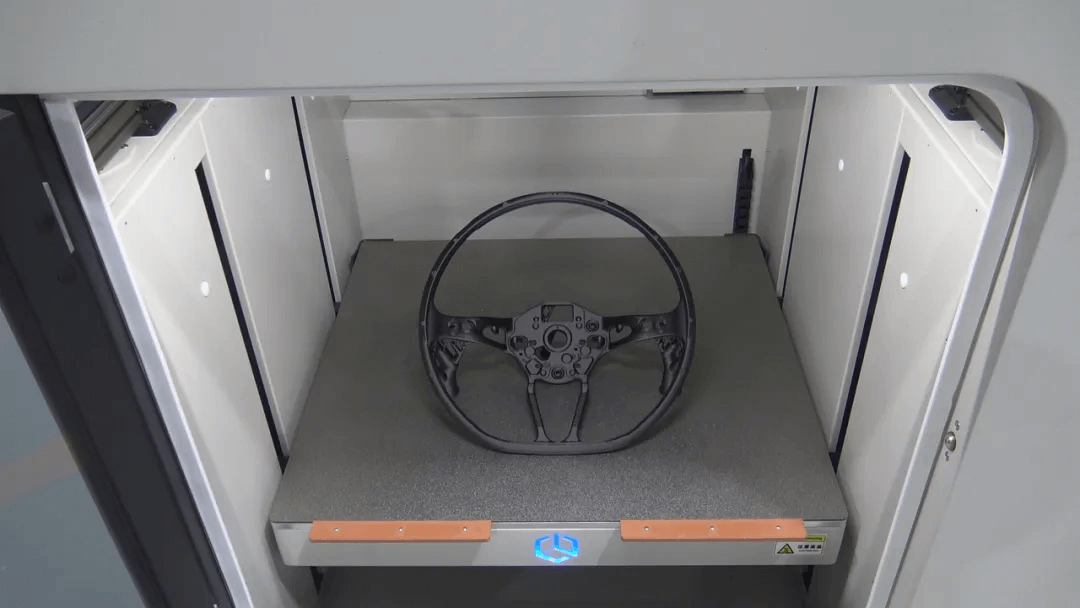

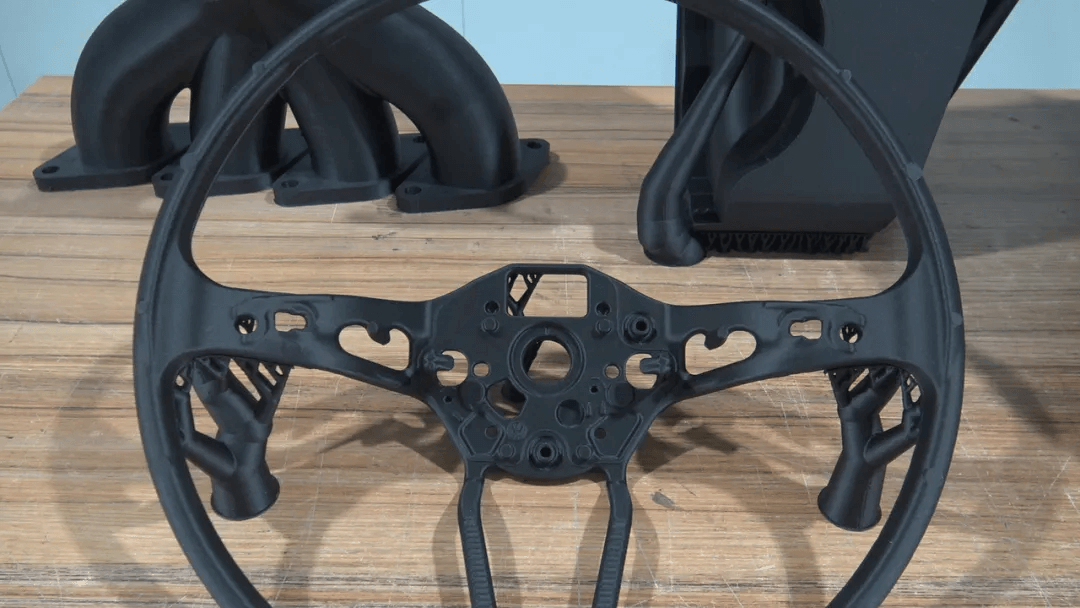

Steering Wheel Mold —— All the details on the steering wheel can be accurately presented through 3D printing, and unique textures and shapes can be customized according to different vehicle models and user needs.

▲ D600 Pro2 HS © Creatbot Technology

▲ D600 Pro2 HS © Creatbot Technology

• Material: PET-CF

• Weight: 2.4 kg

• Printing Time: 65 h

• Dimensions: 750*390*375 mm

▲ D600 Pro2 HS © Creatbot Technology

▲ D600 Pro2 HS © Creatbot Technology

03

Three Core Advantages of Choosing PET-CF

- High-Strength and Heat-Resistant Structure

• Carbon Fiber Reinforcement Mechanism: Chopped carbon fibers are embedded in the PET matrix to form a three-dimensional stress network. The tensile strength is > 85 MPa, and the heat distortion temperature reaches 210°C (no softening risk in car暴晒 environment).

• Engineering Value: It can achieve lightweight design under the requirements of large-scale prototypes, and can be used for product verification under high-strength and extreme outdoor environments. It has passed the 200 kg dynamic fatigue test (no cracks after 100,000 cycles).

- Precise and Stable Molding

• Low Shrinkage Characteristics:

Carbon fibers inhibit the crystallization shrinkage of PET, ensuring the dimensional stability of large-sized parts.

• Industrial-Grade Surface Quality:

The interlayer bonding force is increased by 40%, and the layer lines are almost invisible, achieving a smooth transition of the model surface.

• Harsh Environment Adaptability:

Printing temperature: 260 - 290°C (requires a high-temperature printer).

PET-CF is particularly suitable for high-temperature working conditions (such as electric vehicle battery compartment covers) and chemical exposure scenarios (such as oil filter housings), etc. Its environmental tolerance provides "maintenance-free protection" for automotive parts.

- Full Lifecycle Cost Advantage

• Manufacturing Efficiency: 3D printing shortens the manufacturing cycle in terms of process, production time, and iteration cost.

• Iteration Flexibility: 3D printers can directly output print files with zero mold costs.

• Environmental Cost: 100% recyclable materials comply with the automotive closed-loop standard.

04

Strength Builds Quality

Our company's 3D printers are the solid backing for creating these high-quality models. The high-precision print heads and advanced control systems enable each model to achieve millimeter-level accuracy, ensuring that the design drawings are perfectly transformed into physical objects. The wide material compatibility is also a major highlight. Whether it's high-strength engineering plastics or composite materials with special properties, they can all be easily handled to meet the strict material requirements of different parts of cars and electric vehicles. In addition, the high printing speed significantly improves production efficiency, reducing production costs while ensuring quality. With these advantages, we can provide customers with one-stop services from design to printing, quickly meeting diverse customization needs.