Industrial 3D Printing Consumables Selection Guide: From Performance Requirements to Precise Matching.

Core Selection Logic: Start with Application Requirements

Abandon the thinking of "which material is the best" and focus on "which material is most suitable for the tasks my parts need to accomplish":

- Core Performance Requirements: Strength, stiffness, toughness, impact resistance, wear resistance, fatigue resistance?

- Environmental Tolerance: Operating temperature range? Chemical resistance required (which chemicals)? Weather resistance required (UV, humidity)?

- Functional Requirements: Biocompatibility needed? Food contact certification? Flame retardancy? Electrical insulation/conductivity? Dimensional stability?

- Precision and Appearance: Requirements for dimensional accuracy, surface finish, and detail presentation?

- Cost and Efficiency: Are material costs, printing speed, and post-processing complexity within the budget and schedule?

01

Analysis and Selection Recommendations for Mainstream Industrial Consumables

(1) Basic Industrial Materials: Pursuing High Strength, High Stiffness, and Heat Resistance

- ABS (Acrylonitrile Butadiene Styrene)

Core Advantages: Excellent comprehensive mechanical properties (balanced strength/toughness), resistant to common chemicals, cost-controllable, can be polished with acetone to improve surface quality.

Typical Applications: Automotive interior parts, durable prototypes, tooling fixtures, electronic enclosures.

- ASA (Acrylonitrile Styrene Acrylate)

Core Advantages: Similar mechanical properties to ABS, but with UV resistance and high-temperature resistance, does not yellow or embrittle after long-term outdoor use, better chemical resistance than ABS.

Long-term Use Guide: Requires dry storage to ensure printing quality.

Typical Applications: Automotive exterior parts, outdoor sensor housings, architectural landscape components.

(2) High-performance Industrial Materials: Pursuing a Balance Between Weather Resistance and Toughness

- ABS-CF (Carbon Fiber Reinforced ABS)

Core Performance: 25% glass fiber/carbon fiber filling, rigidity increased by over 50%, outstanding mechanical properties, excellent dimensional stability, matte surface.

Key Improvements: Due to the large thermal expansion coefficient of ABS-CF, warping or shrinkage may easily occur during the printing process. A high-temperature heated bed and appropriate adhesive are required to reduce these issues.

Typical Applications: High-precision tooling fixtures, clamps, small-batch production parts, lightweight automotive structural parts.

- PET-CF (Carbon Fiber Reinforced PETG)

Core Advantages: Significantly improved stiffness based on PETG, with excellent heat resistance, dimensional stability, and low hygroscopicity, enhanced surface scratch resistance.

Performance Balance Points:

- To maximize the stiffness advantage, it is recommended for anti-bending/anti-deformation scenarios (avoid high-impact loads).

- Use a hardened steel nozzle to ensure long-term printing stability.

Typical Applications: Outdoor mechanical housings, automotive fluid management components, chemical testing fixtures.

- Ultra PA-CF (Carbon Fiber Reinforced Ultra-high Performance Nylon)

Core Advantages: Carbon fiber/glass fiber modified nylon (PA6/66), excellent wear resistance. The addition of glass fiber improves the mechanical properties, heat resistance, and dimensional stability of nylon.

Engineering Optimization Directions:

- Highly hygroscopic (strict moisture protection is required before and after printing), high printing temperature.

- Match with a high-temperature printing system (nozzle ≥260°C) to unleash the material's potential.

Typical Applications: Oil-resistant gears, outdoor sports components, chemical valve seals.

- PET-GF (Glass Fiber Reinforced PETG)

Core Performance: 20% glass fiber reinforcement, high surface finish, better toughness, suitable for impact-resistant scenarios (such as mechanical housings).

Typical Applications: Aerospace structural parts, non-metallic parts around automotive engines.

(3) Ultra-high Performance Industrial Materials: High Temperature, High Strength, Special Applications

- PEEK (Polyetheretherketone) & PEKK:

Advantages: Top-tier engineering plastics! Mechanical strength comparable to metals (especially maintains well at high temperatures), excellent chemical resistance (resistant to almost all solvents), low smoke and non-toxic, excellent wear resistance and dimensional stability, biocompatible (can be sterilized and used for implants).

Professional Manufacturing Requirements:

- Need to match with an ultra-high temperature industrial printing system.

- Full-process closed-loop temperature control and moisture-proof management to ensure material performance stability.

Applications: Aerospace (non-metallic parts around engines, ducts), medical (surgical guides, implants), automotive (high-performance engine compartment parts, sensors), oil and gas (chemical-resistant seals, valve components), semiconductor manufacturing fixtures.

- Ultem (Polyetherimide, PEI)

Core Performance: Long-term temperature resistance of 170–220°C, top-notch dimensional stability, flame-retardant/low smoke and non-toxic, certified by FDA/aerospace.

Sustainability: The first bio-based PEI (25.5% of raw materials from waste), with a 10% reduction in carbon footprint.

Typical Applications: 5G base station components, aircraft interior panels, high-pressure sterilized surgical instruments.

- Selection Notes: Only suitable for professional-grade industrial printers (such as PEEK250 or PEEK300, etc.). The material handling and printing process have extremely high requirements. The printing temperature of PEKK is slightly lower than that of PEEK, and the crystallinity control is different. It is recommended to use the one-stop annealing process of PEEK250 to optimize the crystallinity of parts.

02

Selection Pitfall Avoidance Guide: Key Considerations

- Printer Capability Matching: This is the prerequisite. Confirm whether your printer can reach the required temperatures (nozzle, heated bed, chamber) for the material, whether it has a closed constant-temperature chamber, and whether the extrusion system can handle (e.g., reinforced materials).

- Material Drying: Hygroscopic materials such as UltraPA-CF, PEEK, ABS, and ASA must be dry before printing. Printing with wet materials will lead to reduced strength, bubbles, and interlayer cracking.

- Print Parameter Optimization: The optimal print parameters (temperature, speed, cooling, retraction) may vary for different materials or even different brands/batches of the same material. It is necessary to refer to the manufacturer's recommendations and conduct small sample tests.

- Pay Attention to Post-processing Requirements: Is annealing required (to improve crystallinity, strength, heat resistance)? Is surface treatment required (grinding, painting, vapor polishing)? Post-processing may significantly change the material properties.

- Comprehensive Cost Evaluation: Consider the material unit price, printing success rate (scrap rate), printing time (power consumption), and post-processing costs. Although PEEK is expensive, it may replace more expensive metal machined parts.

03

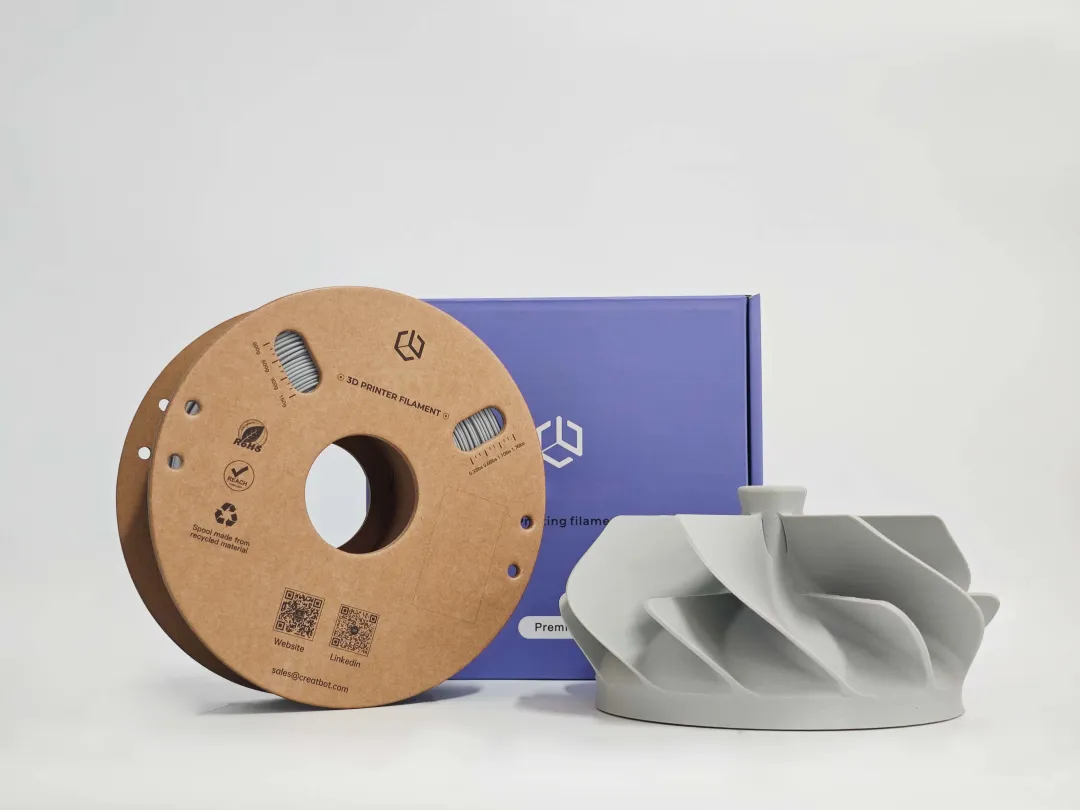

Suwei Technology Industrial 3D Printing Solutions

We offer a wide range of 3D printing solutions and high-performance industrial-grade 3D printing materials, specially designed for harsh application environments and perfectly matched with the high-temperature and constant-temperature capabilities of Suwei Technology industrial 3D printers.

Deeply understanding material characteristics, clarifying application requirements, and perfectly matching the capabilities of 3D printing equipment are the keys to ensuring printing success and meeting part performance standards. Avoid choosing "by feeling" and make decisions driven by professional knowledge and data, so that 3D printing can truly become your powerful tool to overcome industrial challenges.