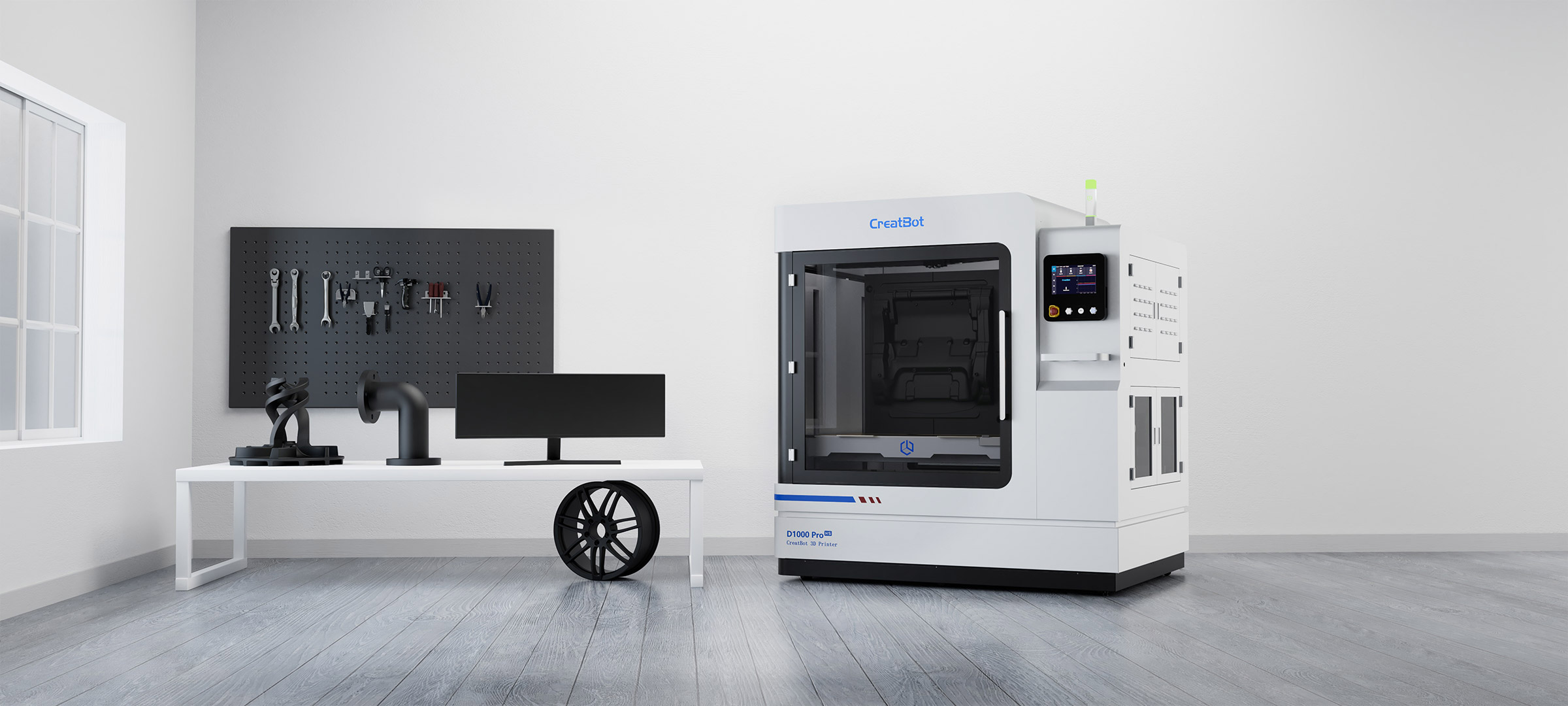

D1000 Pro HS

The Ultimate In-House Solution:

Industrial-Grade 1-Cubic-Meter Smart High-Speed 3D Printer

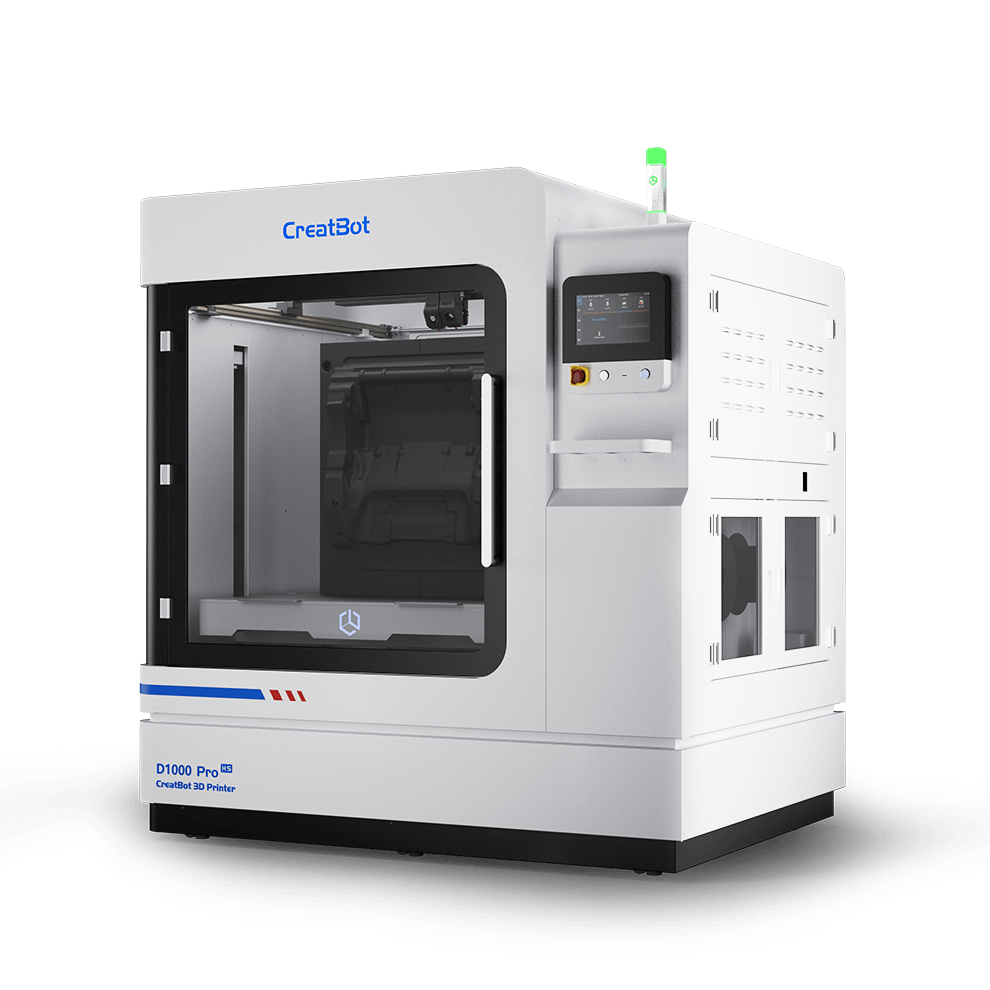

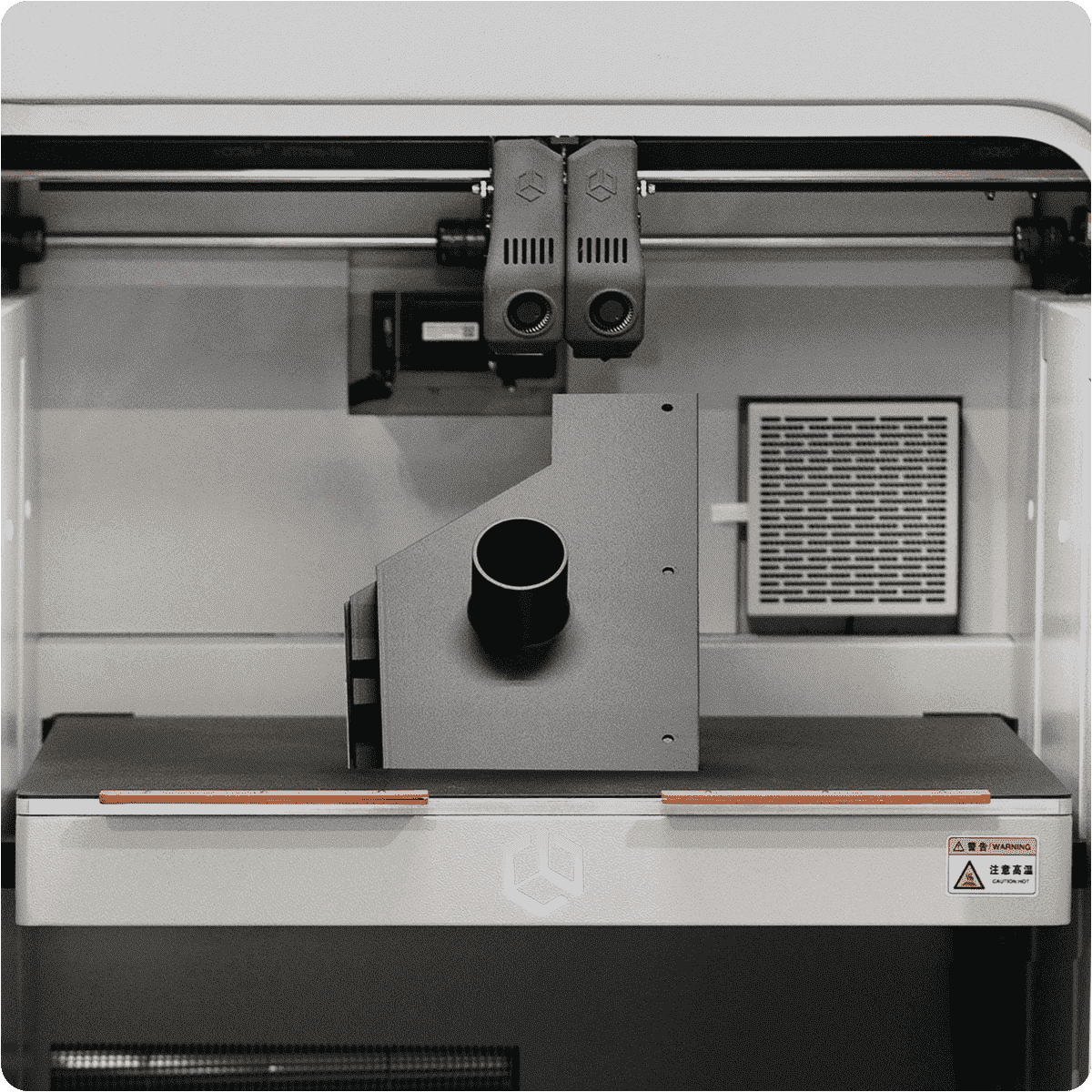

The D1000 Pro HS represents the ultimate evolution in large-format 3D printing, delivering significant advances in usability, stability, and safety. This new high-speed version achieves a stable printing speed of 300 mm/s and is engineered to produce large, full-size parts, prototypes, tools, and molds in-house with unprecedented efficiency.

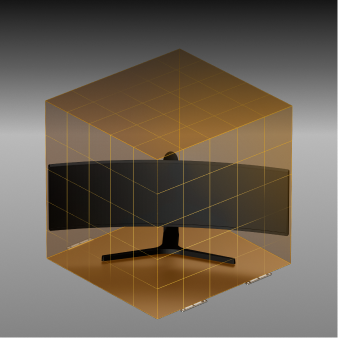

Featuring a massive build volume of 1050×1050×1050 mm, it handles big projects with ease. Compatible with large 2×5 kg spools of materials such as PLA, ABS, ASA, PET-CF, PA-CF, and PPS-CF, it enables continuous, uninterrupted printing of large-scale models. Every component is manufactured to the highest standards, ensuring reliable and consistent performance.

Every time. Every part. No mistake.

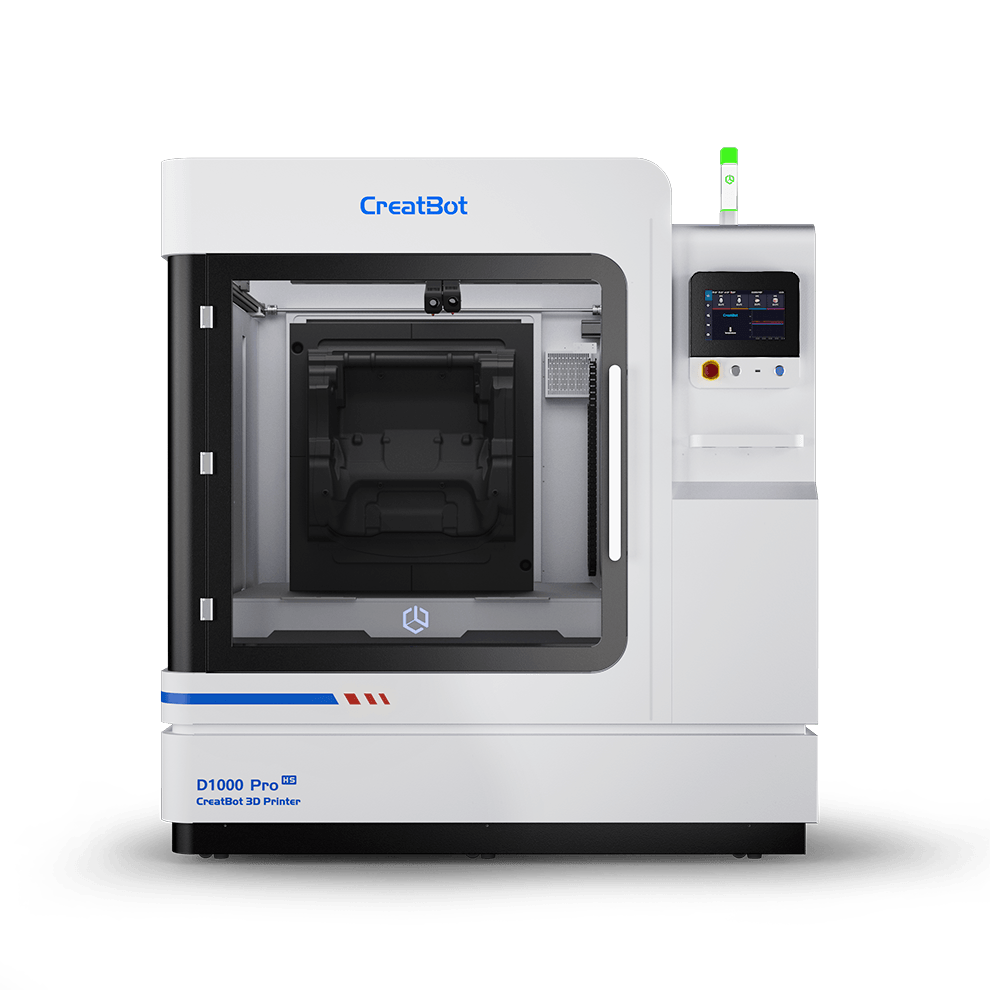

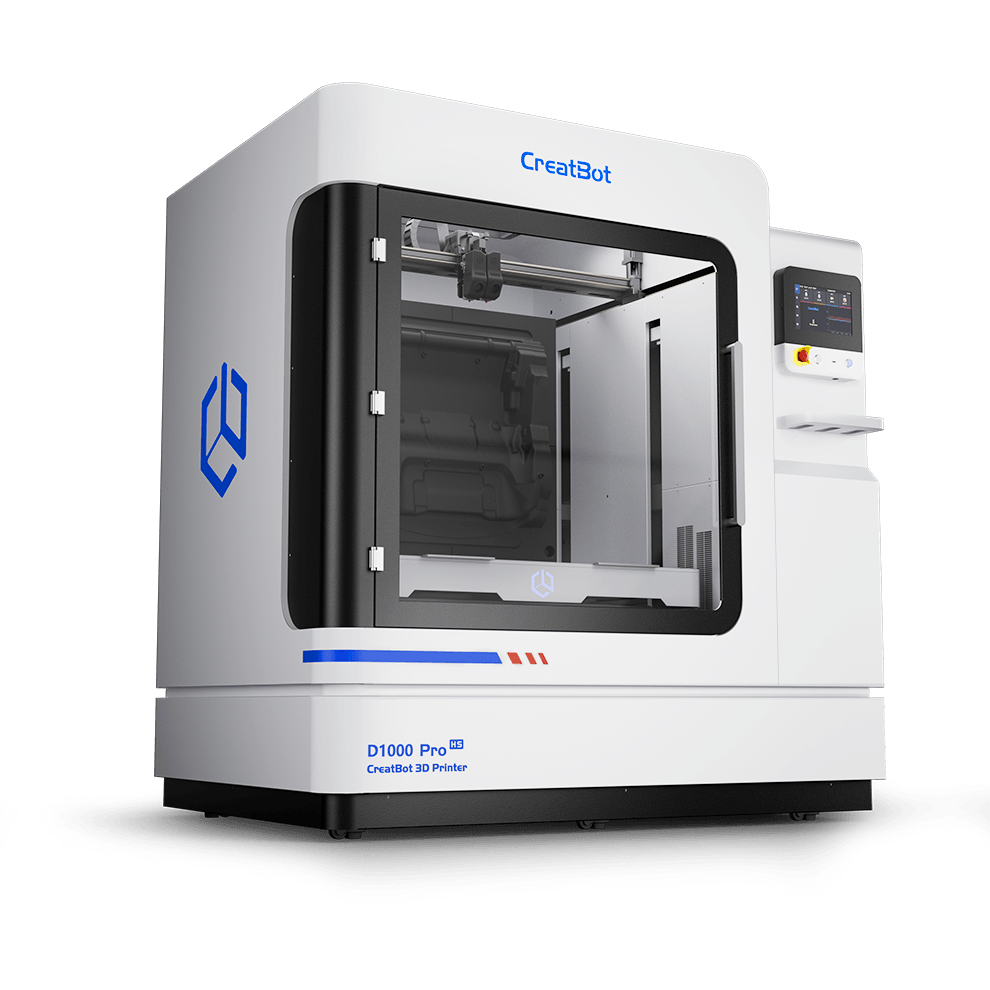

D1000 Pro HS

One Cubic Meter Industrial Grade Large 3D Printer.

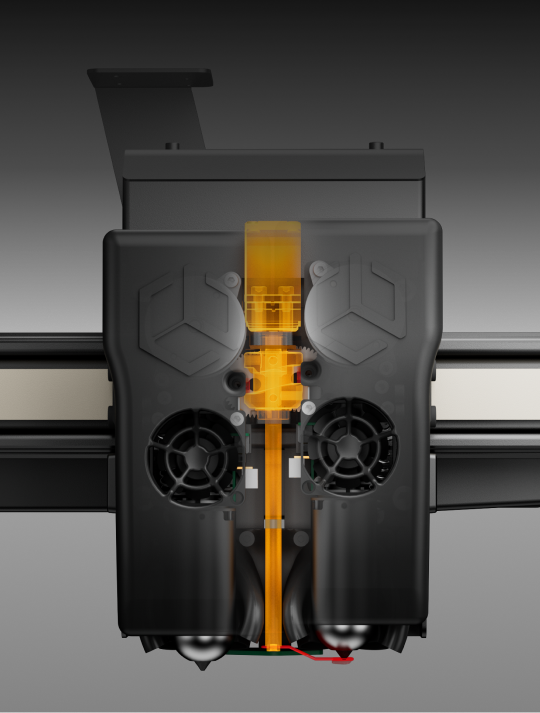

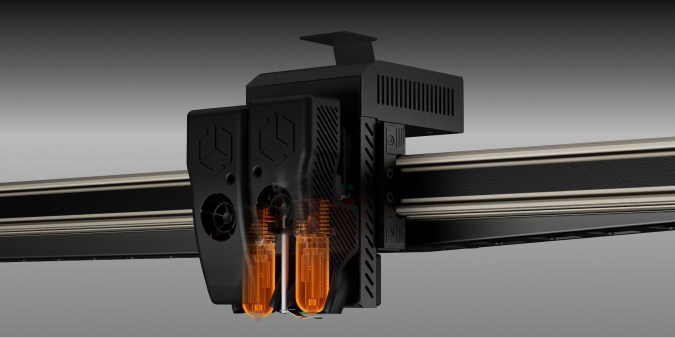

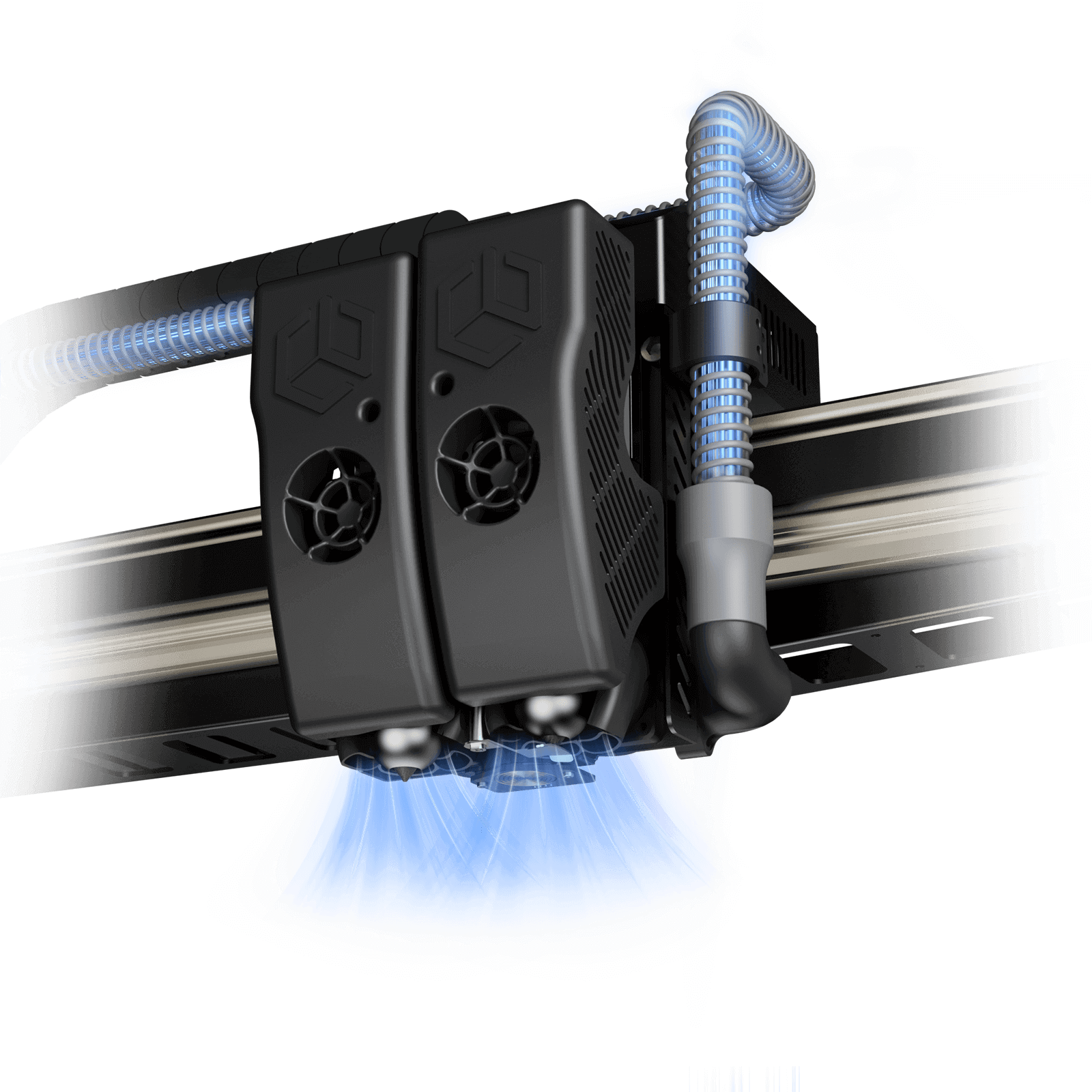

D1000 Pro HS is upgraded from the model D1000,it is a new high-speed printing version based on the in-depth development of Klipper. It adopts a new hotend with a flow rate of up to a record-breaking 90 mm³/s. The stable printing speed can reach 300mm/s, which is 5 times the speed of the D1000 model.

With a build volume of over 1050*1050*1050mm, it is the perfect machine for creating large and full size parts, prototype, tools, molds, jigs & fixtures in-house. Within days you can have a fully functional high quality prototype. CreatBot big rolls filament of PLA, ABS, ASA, PA-CF, etc suit well for your big models without worrying frequent replacement of filament. All its features manufactured to the highest standards. Every time, every parts, no mistake.

Every time, every parts, no mistake.

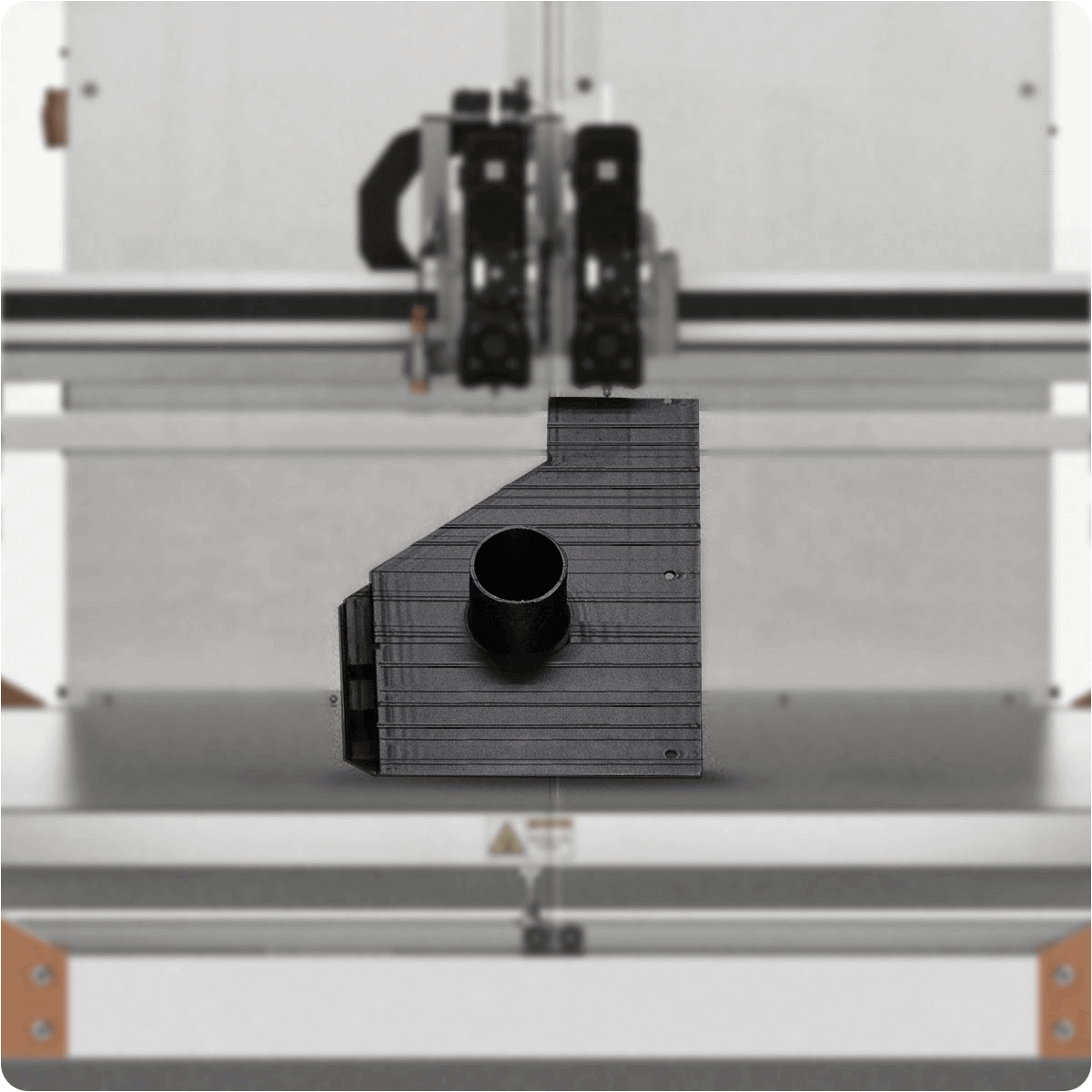

Scale Without Limits for High-Strength Prototypes

The CreatBot D1000 Pro HS was created to make industrial 3D printing of large-scale objects and prototypes as easy as possible. It is embedded with many advanced technologies for ultra-large, impressive prints. It will undoubtedly be your best choice if you are looking for an industrial large-scale 3D printer for prototyping with engineering-grade materials.

If you are tired of the fragility of PLA and the warping of ABS, try our revolutionary material, UltraPA-CF. By printing your large models with a large-diameter nozzle, you will get an oversized model with a high strength of 80MPa and heat resistance up to 150°C within days. It is the best choice for your prototype verification.

Scale Without Limits for High-Strength Prototypes

The CreatBot D1000 Pro HS was created to make industrial 3D printing of large-scale objects and prototypes as easy as possible. It is embedded with many advanced technologies for ultra-large, impressive prints. It will undoubtedly be your best choice if you are looking for an industrial large-scale 3D printer for prototyping with engineering-grade materials.

Design Prototype

Functional Prototype

End-Use Parts

Spare Parts

Forms & Molds

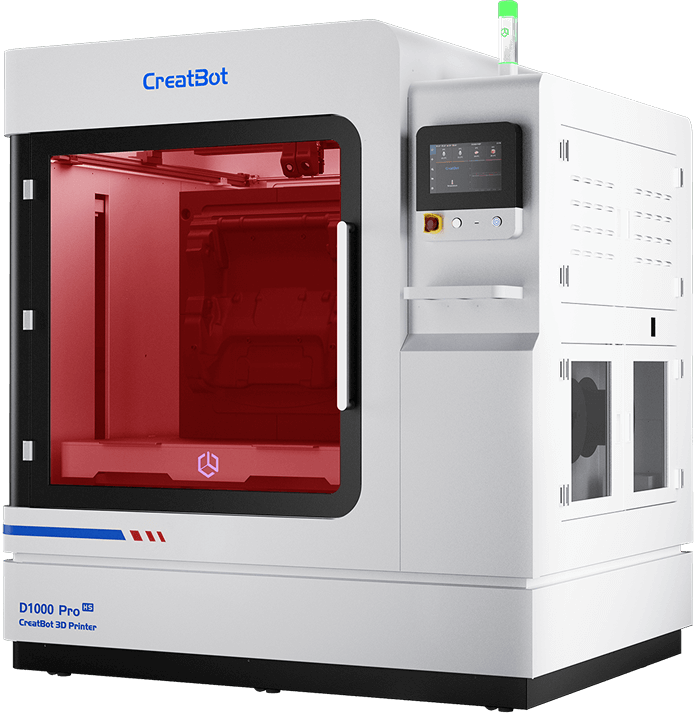

When printing large or high-strength engineering materials (e.g., ABS), uneven cooling causes internal thermal stress, leading to warping, delamination, or cracking.

Did You Know a Heated Chamber Can Warp Your Printer?

Ln large-format FFF 3D printing, when chamber temperature rises, the printer frame and structural components also undergo thermal deformation—metal expansion, axis misalignment, and mechanical part displacement. These micro-distortions accumulate layer by layer, ultimately leading to:

- - Layer Misalignment and Surface Roughness

- - Loss of Dimensional Accuracy

- - Structural Defects in Large Parts

This is why treating chamber temperature as an optional add-on, or claiming it can be retrofitted later, proves these manufacturers just don't get it. They have no compensation for machine deformation—some aren’t even aware of the issue. They simply add it as a feature to drive sales, with total disregard for actual print quality.

With 8+ Years of R&D on the Chamber Temperature of FFF Industrial Printers

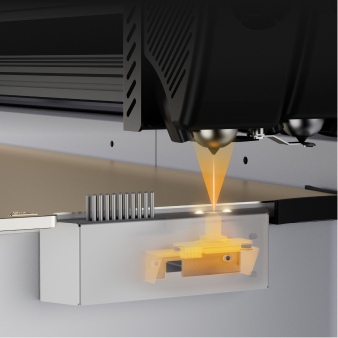

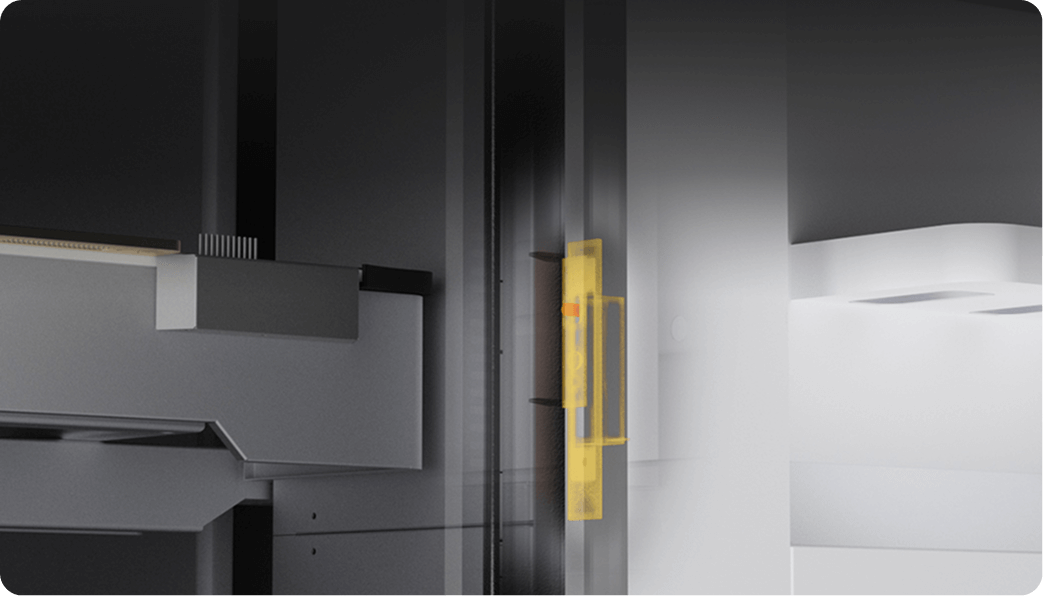

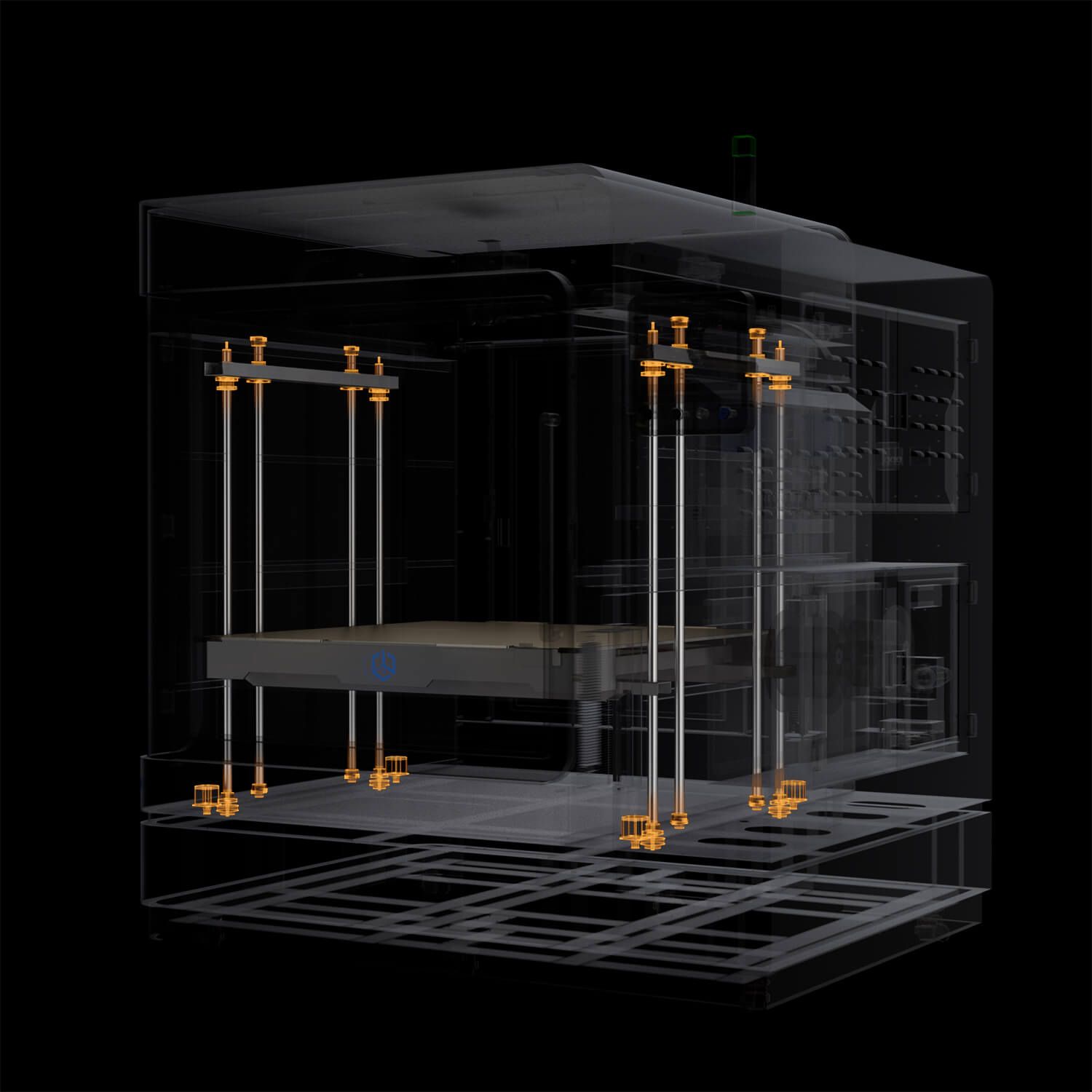

Our Solution: The Synergy of Two Patented Technologies—Intelligent Chamber Heating Algorithm & Z-Axis Magic Box Technology:

- Intelligent Heating Algorithm: Predicts and counteracts irregular deformations caused by chamber temperature variations

- Z Axis Magic Box: Maintains flawless surface finish via real-time thermal compensation for frame and build-plate expansion.

- Ultimate Result: Flawless prints produced even when slight machine deformation has already occurred!

- Machine Weight Matters: Our robust construction significantly minimizes deformation. The heavier the machine, the less distortion occurs!

With 8+ Years of R&D on the Chamber Temperature of FFF Industrial Printers

Our Solution: The Synergy of Two Patented Technologies—Intelligent Chamber Heating Algorithm & Z-Axis Magic Box Technology:

- Intelligent Heating Algorithm: Predicts and counteracts irregular deformations caused by chamber temperature variations

- Z Axis Magic Box: Maintains flawless surface finish via real-time thermal compensation for frame and build-plate expansion.

- Ultimate Result: Flawless prints produced even when slight machine deformation has already occurred!

- Machine Weight Matters: Our robust construction significantly minimizes deformation. The heavier the machine, the less distortion occurs!

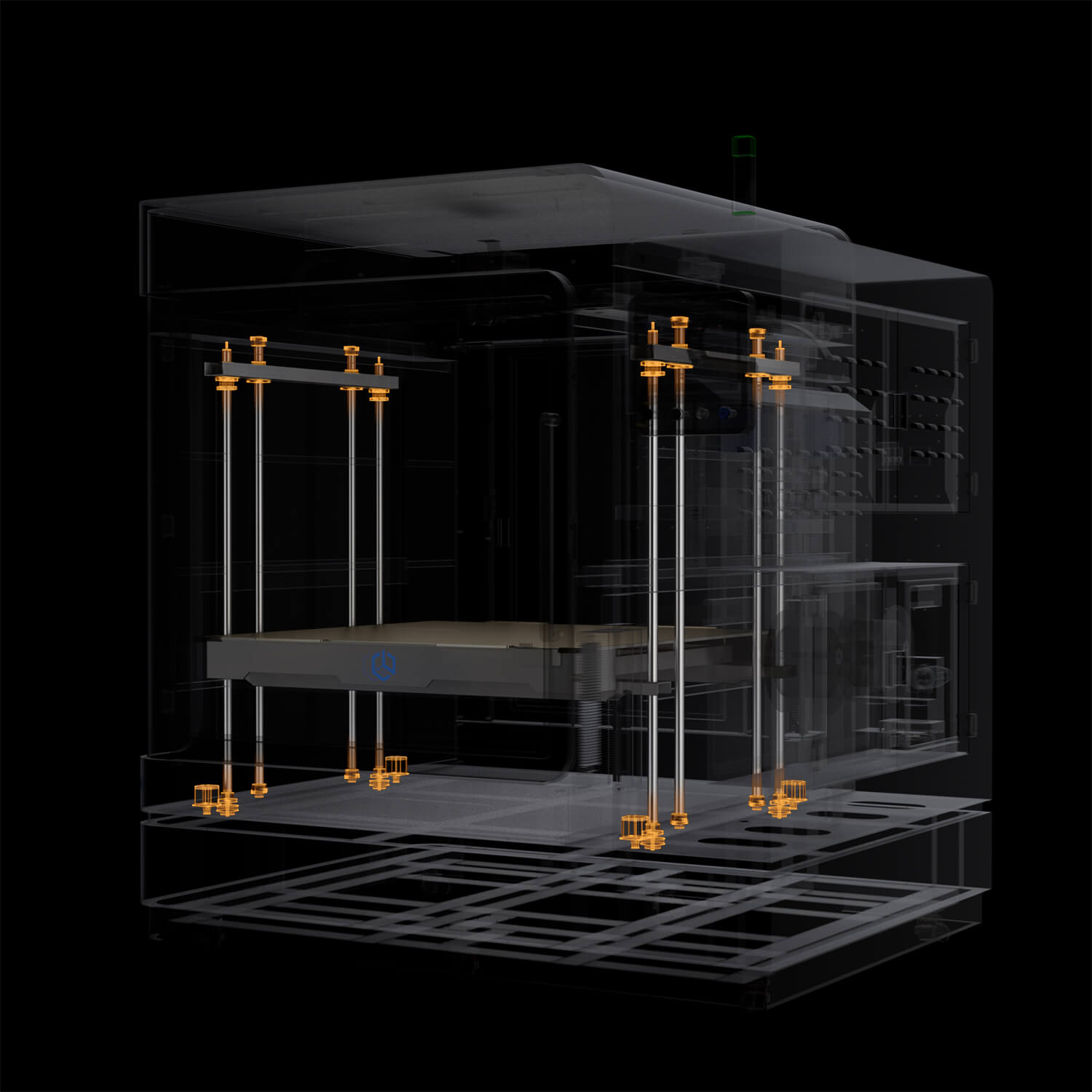

Magnetic Suction Platform

Eliminate Manual Leveling for Absolute Flatness: The independent four-motor drive allows for individual height compensation at each corner of the platform. The system automatically detects and fine-tunes the vertical height of every corner to ensure extreme parallelism between the build plate and the gantry, completely solving first-layer adhesion issues for large-scale prints.

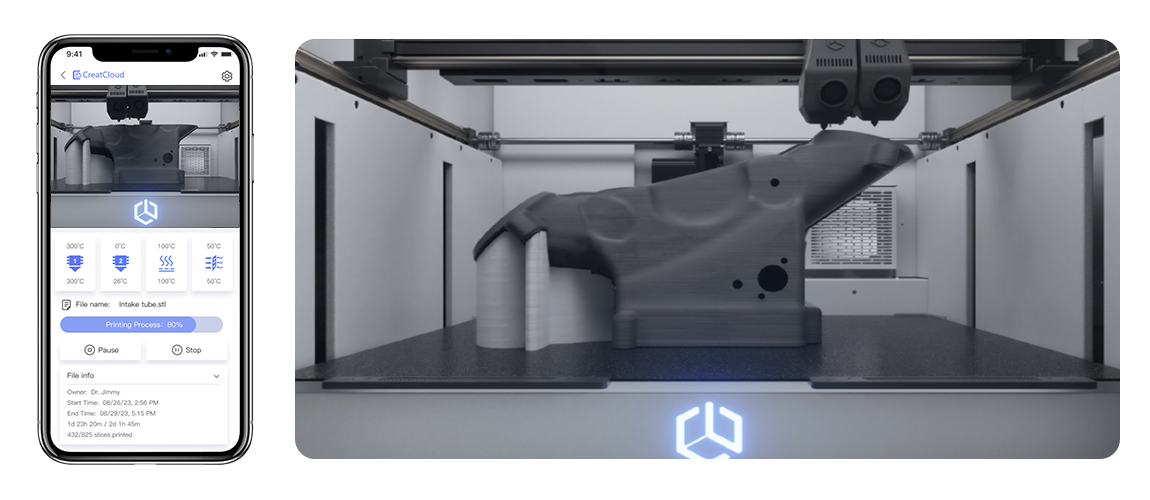

Camera Control Technology

D1000 Pro HS Highlights

- 1050*1050*1050mm Build Volume

- High Resolution & Speed

- Camera Control Technology

- Reliable 24/7

- Fully Enclosed

Exceptional Stability

The precision-engineered steel monocoque construction ensures exceptional machine stability, minimizing vibration and maintaining consistent print quality even during high-speed, long-duration printing sessions. This robust design guarantees reliable performance for industrial-scale production.

Specifications

| Printing | |

| Print Technology | FDM/FFF |

| Build Volume | Single Extrusion: 1050 x 1050 x 1050mm Dual Extrusion: 990 x 1000 x 1000mm |

| Number of Nozzles | Double |

| Auto Rising Extruders | Yes |

| Layer Resolution | 0.05 mm |

| Filament Diameter | 1.75 mm |

| Filament Compatibility | PLA, ABS, ASA, PP, PETG, PC, Nylon, TPU, ABS-CF, PC-CF, PET-CF, PET-GF, UltraPA-CF, PPS-CF, etc |

| Nozzle Diameter | 0.8 mm (0.3-1.0 mm) Optional |

| Print File Type | Gcode |

| Temperature | |

| Max. Nozzle Temperature | 420 ℃ |

| Max. Bed Temperature | 100 ℃ |

| Hot Chamber Temperature | 80 ℃ |

| Filament Dry Room Temperature | 0 ℃/70 ℃ |

| Speed | |

| Max Print Speed | 300 mm/s |

| Flow Rate | 90 mm³/s |

| Electrical | |

| Power Requirements | 220~240 V, 50~60 Hz |

| Display | 10-inch full color touch screen independent operating system (multi-language) |

| Rated Power | Printer: 5500W, Chamber: 6000W |

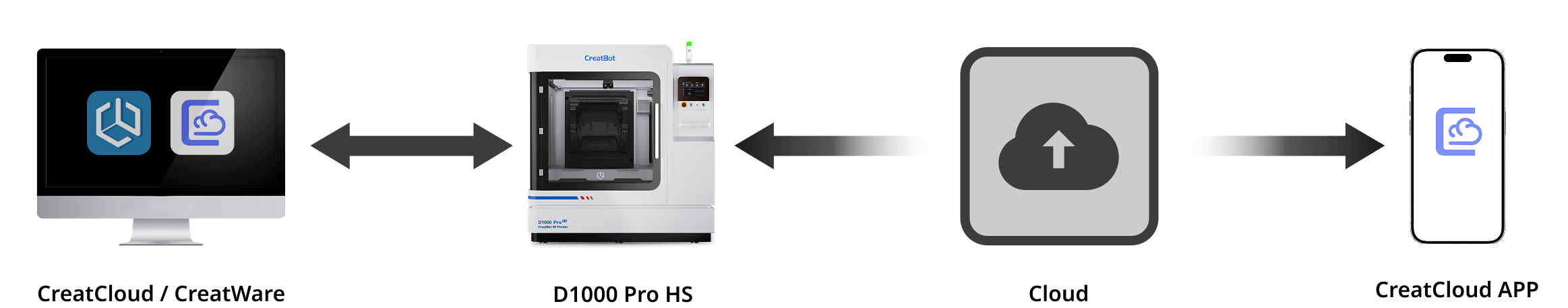

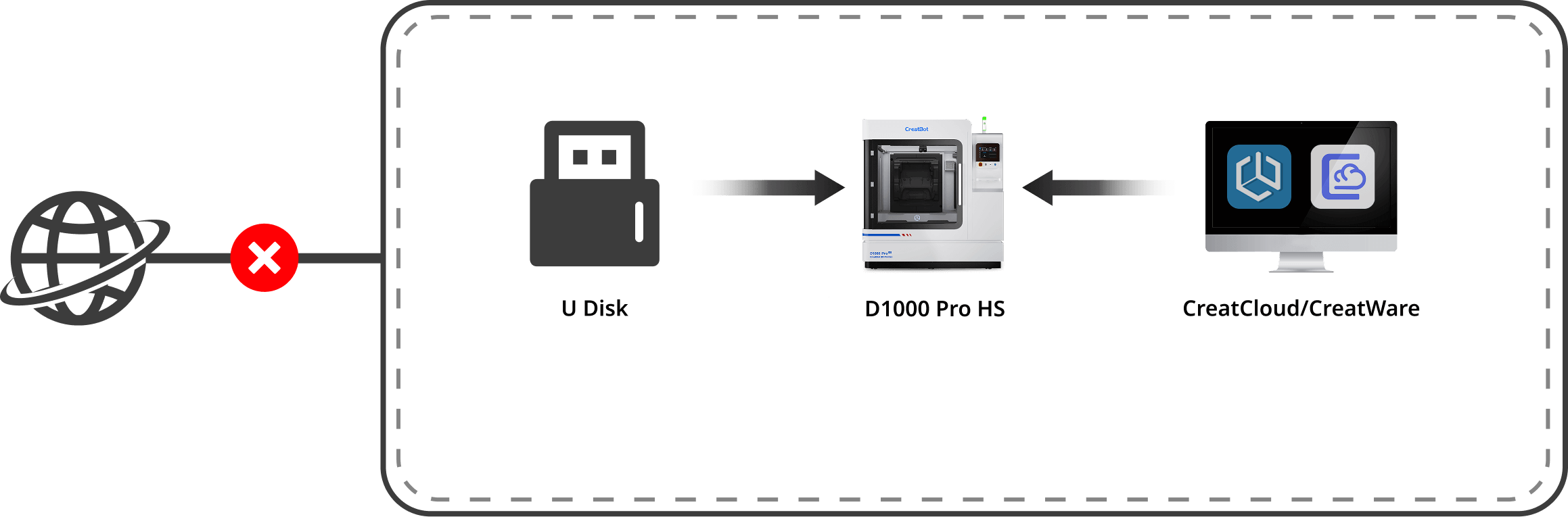

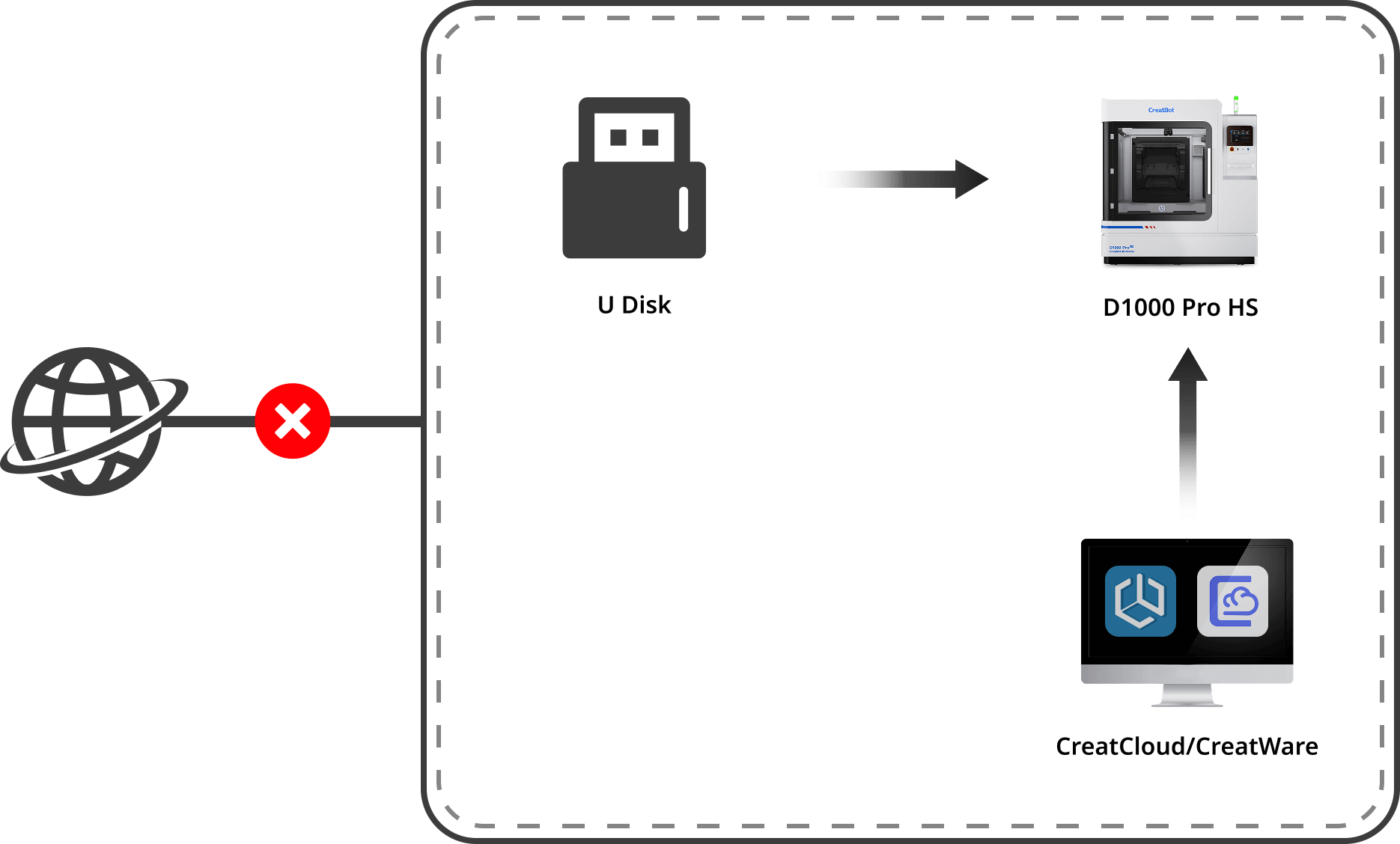

| File Transfer | USB/U disk / WiFi / LAN |

| Software | |

| Software | CreatWare, Orca Slicer, Cura, Simplify3D,Prusa, etc |

| Supported File Types | STL, OBJ, Gcode, AMF, STP, STEP |

| Operating Systems | Windows ALL / Mac OS |

| Special Function | |

| Air filter | HEPA+Carbon |

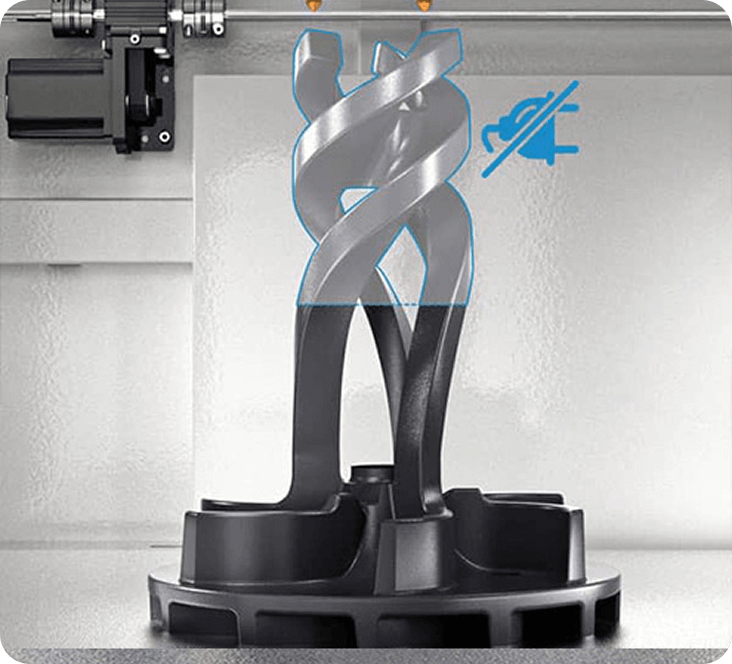

| Filament Detection | Pause Printing |

| Firmware | Klipper - High Speed |

| Camera Control | Camera Remote Monitoring |

| Dual Nozzle Auto-Resume Printing | Yes |

| Bed Leveling Technology | Eddy Current Leveling |

| XY Offset Technology | HD Camera Dual Nozzle Offset |

| Z Offset Technology | Dual Photoelectric Sensor |

| Nozzle Shutter Technology | Dual Nozzle Shutter |

| Door Opening Detection | Safety Door Lock |

| Chamber Insulation | Internal Insulation Cotton |

| External Air Cooling | Yes |

| Mechanical | |

| Build Plate | Aviation Aluminum Plates |

| Build Plate Leveling | Automatic |

| Extruder | Smart Dual Extruders |

| Auto-Raising Extruders | Yes |

| X/Y Positioning Precision | 0.011 mm |

| Z Positioning Precision | 0.0025 mm |

| Z-Axis Structure | Independent Quad-Z Axis |

| Size & Weight | |

| Product Dimensions & Weight | 1870 x 1430 x 1940mm 750kg |

| Packing Size & Weight | 2070 x 1610 x 2240mm 880kg |

NEED HELP DECIDING?

We've put together a comprehensive comparison of our 3D printers, so you can find the one that's right for your needs.